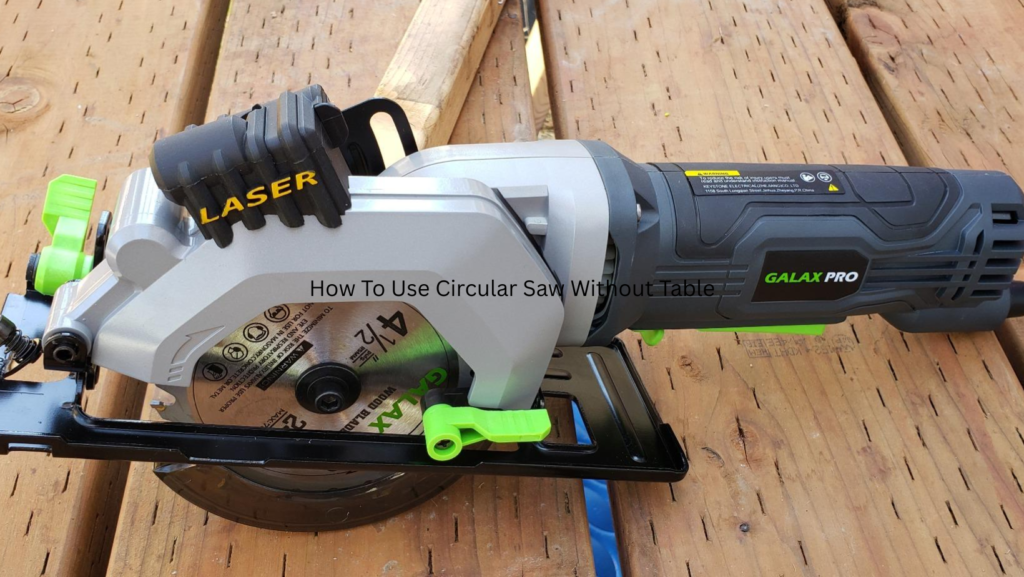

Ever need to cut wood but don’t have a table? I’ve been there just me, a circular saw, and a sheet of plywood on the ground. Most people don’t own a full workshop, and that’s okay. You can still make clean, straight cuts without a table if you know a few easy tricks. In this guide, I’ll show you how to use a circular saw without a table and share tips that helped me. I’ll even add a few ideas for when you don’t have any saws. How To Use Circular Saw Without Table.

Is It Safe To Use a Circular Saw Without a Table?

Yes, it’s safe to use a circular saw without a table—as long as you set things up right. I remember the first time I tried it. I was cutting a board on the ground, hoping it wouldn’t shift or snap. I was a bit nervous, but once I used a few simple tools, it worked out great.

Most people worry the wood will move or the saw will jump. That can happen, but only if you don’t support the board well. Sawhorses, clamps, or even foam sheets can help. The goal is to hold the wood steady so the saw can glide through clean and smooth.

Bad cuts don’t come from not having a table—they come from poor prep. Always wear safety gear, check your blade depth, and make sure the board is solid before you start. I always give it a shake to be sure it won’t move.

So if you’re asking how to use a circular saw without a table, here’s the short answer: yes, you can. Just stay safe, take your time, and set things up right.

Essential Tools & Setup

Before I cut anything, I like to set up my tools. It helps me stay safe and get a clean cut. Here’s what I use every time.

Circular Saw (Corded or Cordless)

This is the main tool. I check that the blade is sharp. I also set the right depth before I start. A corded saw is strong. A cordless one is easy to move.

Sawhorses or a Flat Surface

I use two sawhorses to hold my wood. If I don’t have them, I put foam sheets or boards on the ground. The wood must stay still.

Clamps

Clamps hold the wood in place. They also hold my guide. If the wood moves, the cut can go wrong.

Straightedge or Guide

A straightedge helps the saw move in a straight line. I use a level or the side of a board. I clamp it down tight.

Measuring Tape and Pencil

I measure and mark before I cut. I draw a line where I want to cut. I mark an “X” on the side I don’t need.

Safety Gear

I wear goggles to keep dust out of my eyes. Gloves help me avoid splinters. I use earplugs when the saw is loud.

With these tools ready, you’ll feel more sure and safe. Setup takes a few minutes, but it saves a lot of trouble later.

How to Cut Straight With a Circular Saw (Without a Table)

You don’t need a table to make a straight cut. Just use the right tools and take your time. It’s easier than you think.

Step-by-Step: Use a Guide

Here’s the simple trick: Clamp a straight edge and let the saw follow it.

I place my wood on two sawhorses. Then I mark where I want to cut. I grab a straight board or a level and clamp it down. The saw rides along the edge, like a train on tracks.

My First Time Trying This

The first time I tried, I cut freehand. Big mistake. The blade wobbled, and my line looked all over the place.

Next time, I used a guide. I clamped a straight 2×4 to the wood. That made a huge difference. The saw stayed on course, and the cut came out clean.

Freehand vs. Guided Cuts

Cutting by hand sounds fun, but it’s not easy. Even a small move can mess up the cut. That’s why I use a guide every time.

A straight edge makes it simple. I often use the factory edge of the plywood. Or a long level. Or even a spare board.

Clamp it tight, and the saw will go straight.

Short answer: A guide keeps your cut straight and clean. Use one.

Cutting Plywood With a Circular Saw

Plywood can be tricky. It’s big and can splinter at the edge.

Here’s my trick: Put painter’s tape over your cut line. It stops the top layer from tearing.

Also, use a sharp blade made for plywood. It makes a big difference.

I lay the plywood on foam boards. That holds it flat and keeps the saw from hitting the ground.

Alternative Cutting Platforms (If You Don’t Have a Table or Sawhorses)

Don’t have sawhorses? That’s okay. I’ve been there, cutting wood in a backyard or on a driveway. You just need a safe, flat spot to work.

Foam Sheets Work Great

I like to use foam insulation boards. I lay them on the ground and put my wood right on top. The foam holds it up and keeps the blade from hitting the ground. It’s light, cheap, and easy to store.

Quick tip: You can use the same foam many times.

DIY Cutting Setup

No foam? Try this. Use scrap wood, buckets, or bricks to lift the board. Just make sure it won’t tip or slide. I’ve even stacked a few 2x4s to make a quick platform.

What I Do Outside

When I’m outside, I often use foam or set the wood on grass. Grass isn’t perfect, but it works in a pinch. One time, I laid a board across two buckets and it did the job. You don’t need fancy tools—just good balance and support.

Short answer: No table? Use foam, grass, bricks, or scrap wood. Just keep the board steady and make sure your blade has space.

How to Cut Wood Without a Saw (Bonus Tips)

No saw? No problem. I’ve been there. I needed to cut a shelf once, and all I had was a utility knife. It felt silly, but I made it work.

Use a Handsaw or Jigsaw

A handsaw is great for small jobs. It takes more work, but it’s simple and cheap. I’ve cut 2x4s this way when my saw ran out of battery.

If you have a jigsaw, even better. It’s easier to control and good for thin boards. Just clamp the wood so it doesn’t move.

Try a Utility Knife for Thin Wood

Cutting thin panels? A sharp utility knife can help. Score it along a straight line, then snap it. I’ve done this with thin plywood and it worked well.

When to Buy a Saw

If you plan to cut wood often, get a circular saw. Even a basic one will save time. My first saw was cheap and cordless—and I still use it today.

The takeaway: Handsaws and knives are okay for light cuts. But if you’re doing more than that, a circular saw is a smart buy.

Common Mistakes to Avoid

Cutting wood without a table? It can go wrong if you’re not careful. I’ve learned the hard way. Here are some easy things to avoid so your cuts stay clean and safe.

Not Holding Both Sides

If one side hangs in the air, the wood can fall or bend. That’s when your blade binds or the wood snaps.

Simple fix: Support both sides. I use sawhorses, foam boards, or even scrap wood. Just make sure the wood stays flat and steady.

Forcing the Saw or Letting It Jump

One time, my saw kicked back because the wood pinched the blade. It scared me. It also ruined my cut.

That happens when the wood moves or sags. The blade gets stuck and jumps.

Easy fix: Let the blade cut at its own pace. Don’t push. Keep the wood still and let the saw glide.

Skipping the Line Check

A small mistake at the start can mess up your whole cut. I once clamped my guide just a bit off. That tiny shift made the cut way off.

Pro Tips from My Experience

Let the Saw Do the Work

I used to push the saw hard. I thought it would cut faster. It didn’t. The cut came out rough. The saw jumped. It was scary.

Now, I just guide the saw. I hold it steady and let the blade glide. It cuts better and feels safe.

Check Blade Depth Every Time

One time, I forgot to check the depth. The blade cut too deep. It went through the wood and into the foam. It even scraped the ground.

Fast fix: Set the blade about 1/4 inch deeper than the wood.

Now, I check before each cut. It keeps my saw safe. It makes the cut smooth and clean. It’s a simple step—but it matters.

Label Your Leftover Wood

I used to throw scraps in a pile. Later, I’d forget what they were. Was it pine? Was it oak? What size? No clue.

Easy hack: Write a note on each offcut. Mark the type or size.

Now, I grab what I need fast. I use scraps for shims, spacers, or shelves. It saves wood. It saves time.

These tips come from real mistakes. I’ve learned them the hard way. But now I cut smarter, safer, and cleaner. If you’re using a circular saw without a table, start slow, check your gear, and use what you have. You’ve got this.

FAQs: Circular Saw Without a Table (Easy Answers for Real Life)

Can you use a circular saw without a table?

Yes, you can! I’ve done it many times. You just need a safe spot and good support. I use foam boards or sawhorses. Set it up right, and you’ll get a clean cut every time.

What can I use instead of a table when cutting with a circular saw?

You have plenty of options for supporting your wood. Using large foam sheets is a great trick, but I also use things I have lying around, like scrap wood, sturdy buckets, or even bricks. The most important thing is to make sure the board stays perfectly flat and won’t wobble or slide around while you’re cutting.

How do I cut plywood without a table saw?

I lay the plywood on foam boards. Then I mark my line and use a guide. I tape the cut line with painter’s tape to stop splinters. A sharp blade helps a lot.

What’s the best way to make a straight cut with a circular saw?

Use a guide. I clamp a straight board to the wood. The saw follows the edge and stays on track. I tried cutting freehand once—didn’t go well!

How do I avoid splinters when cutting wood?

Tape the cut line with painter’s tape. It keeps the top layer from tearing. Also, use a fine-tooth blade. Go slow and steady.

Conclusion

Yes, you can use a circular saw without a table. It just takes the right setup.

Use what you have. Foam boards, buckets, or even the grass can work. Keep the wood steady. Use a straightedge. Go slow. Let the saw do the job.

I’ve done it many times. I’ve cut wood on the ground, on bricks, even across two chairs. It’s not always perfect—but it works.

The big thing? Stay safe. Wear your gear. Check your setup. Make sure the wood won’t move.

You don’t need a big shop to do great work. You just need a smart plan and a steady hand.

Got a tip that works for you? Or a question about a cut? Drop it in the comments. I’d love to hear from you.

Hi, I’m Tom Scalisi, and welcome to The Saw Blog! I started this blog to share my hands-on experience and insights about woodworking tools—especially saws and saw blades. Over the years, I’ve had the chance to work with a wide range of tools, and I’m here to help both professionals and hobbyists make informed decisions when it comes to selecting and using their equipment. Whether you’re looking for in-depth reviews, tips, or just advice on how to get the best performance out of your tools, you’ll find it here. I’m excited to be part of your woodworking journey!