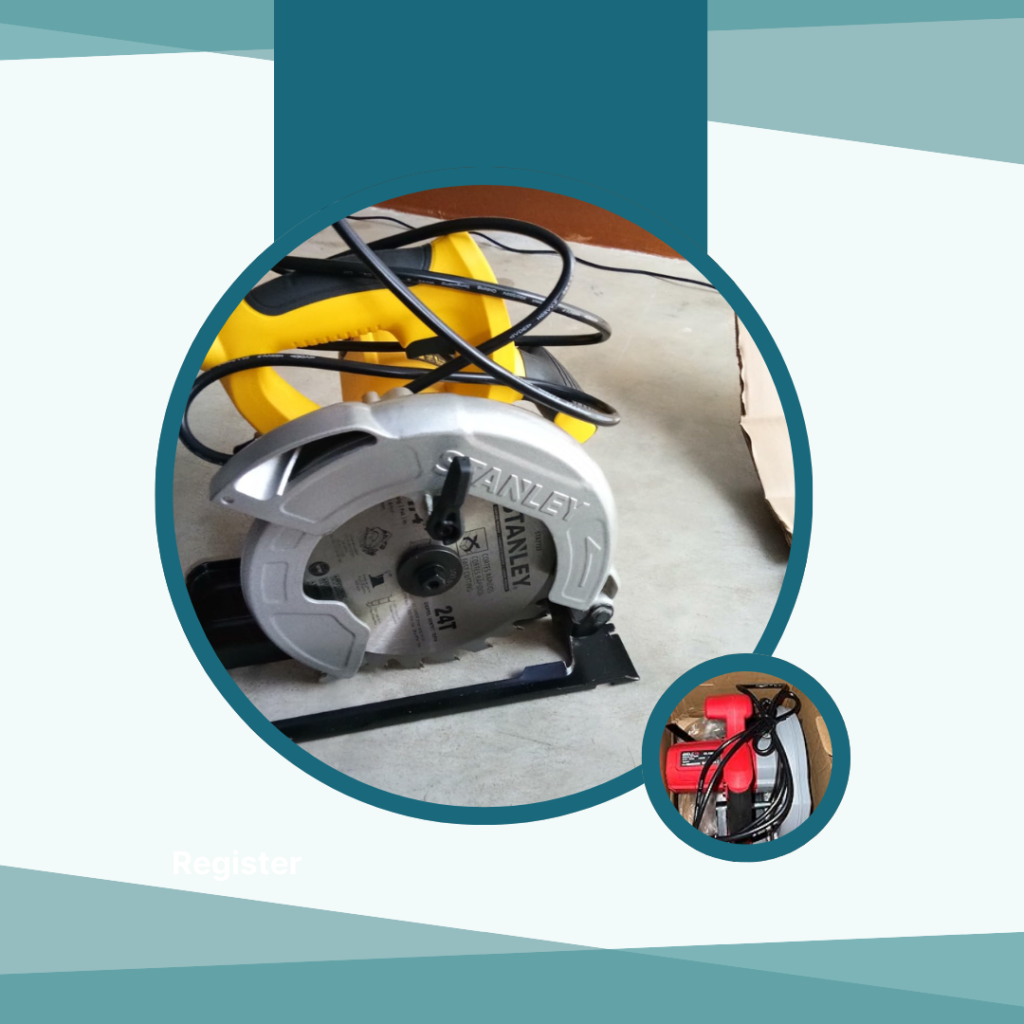

Has your circular saw ever just quit on you right in the middle of a cut? It’s so annoying! But don’t worry too much—it’s actually a pretty common problem, and most of the time, the fix is simple.

If you’re wondering why your saw keeps stopping, you’re definitely not alone. After working with these tools for years, I’ve figured out the main reasons this happens and how to easily solve them. Let’s get your saw back up and running!

Why Your Circular Saw Stops Mid-Cut

The cutting operations of circular saws cause periodic stops and starts during their usage for cutting tasks. That’s super frustrating. The tool carries forward through stage one before it abruptly halts during its second operational phase. But don’t worry! The reasons behind employee operational issues in their professional sphere result in straightforward remedies. Let’s dive in.

A. Dull or Damaged Blade

Using a dull blade during cutting operations becomes nearly impossible, just like trying to cut steak with a boneless knife. The friction produced by dull blades slows down the Saw and creates resistance during cutting operations.

The state of a dull blade becomes evident through wood burn marks combined with uncomfortable pressure that leads to rough cuts.

✔️ Burn marks on the wood.

Your usual effort becomes insufficient to complete the work.

Cutting with a dull blade produces jagged lines instead of neat and steady lines.

Fix: Swap in a sharp blade. Trust me, it’s a game-changer! When I first used the Saw, I was amazed at its silky movement.

B. Not Enough Power

If your Saw isn’t getting enough power, it won’t run right. Weak extension cords cause problems for corded saws, and a low or overheating battery can shut down cordless saws.

Quick fixes:

🔹 Use a heavy-duty extension cord.

🔹 Charge your battery fully before cutting.

🔹 Let an overheated battery cool down.

I once struggled with my Saw stopping constantly—it turned out that my old battery was the issue. A new one fixed it instantly!

C. Cutting Too Fast

Pushing too hard doesn’t speed things up—it makes them worse. The blade binds, the motor strains, and the Saw stops.

Best way to cut:

✅ Let the Saw move at its own pace.

✅ Use light, steady pressure.

✅ If it resists, ease up and check the blade.

Every time I rush, my Saw either stops or kicks back. Slowing down works way better!

D. Wood Pinching the Blade

If the wood squeezes the blade, the Saw stops. Warped wood, knots, or poor support can cause this.

Simple fixes:

✔️ Clamp your material down.

✔️ Use a support board for thin wood.

✔️ Cut in a straight, steady line.

I once cut plywood without support, and the wood bent, pinching the blade. A simple support board solved it!

E. Overheating or Overloading

Saws shut off when they overheat. This happens if the motor works too hard, the blade is dull, or you’re cutting too fast.

Signs of overheating:

🔥 Burning smell.

🐌 Sluggish motor.

⏳ Saw stops after a long cut.

How to prevent it:

🔹 Take breaks so the Saw can cool.

🔹 Cut in steps instead of forcing it.

🔹 Keep vents clean for airflow.

I once ignored the burning smell while cutting. Minutes later, my Saw shut off completely. Lesson learned—pay attention!

How to Use a Circular Saw Safely and Prevent Mid-Cut Stops

A circular saw is a powerful tool, but it works best when used correctly. Follow these simple tips to keep your saw running smoothly and avoid sudden stops.

A. Pick the Right Blade

Using the wrong blade makes cutting harder. The right one gives smooth, easy cuts.

✔️ Match the blade to the material – Wood, metal, and plastic need different blades.

✔️ Check the teeth count – More teeth make smoother cuts. Fewer teeth cut faster.

✔️ Use the right size – A too-big or small blade won’t work well.

B. Keep Your Saw Clean

A clean saw works better and lasts longer. Dust and dirt can make it stall.

✔️ Remove sawdust – It can block air vents and overheat the motor.

✔️ Oil moving parts – A little oil helps things run smoothly.

✔️ Check for damage – Look for loose screws or frayed cords.

C. Cut the Right Way

Pushing too hard or cutting without support can stop the blade or kick it back.

✔️ Let the saw do the work – Press lightly and move steadily.

✔️ Support the material – Use clamps or sawhorses to hold it in place.

✔️ Keep the saw straight – Twisting the saw can jam the blade.

D. Check Power Before You Start

A weak power supply can make your saw stop mid-cut.

✔️ For corded saws: Use a strong extension cord.

✔️ For cordless saws: Charge the battery fully before cutting.

E. Unplug When Not in Use

Always unplug your saw when changing blades, making adjustments, or storing it.

✔️ Prevents accidents

✔️ Protects the motor

✔️ Keeps you safe

FAQs: Quick Answers to Common Problems

Why does my circular saw stop when cutting thick wood?

Thick wood is tough to cut! If your saw stops, the blade may be dull. Pushing too hard can also cause issues. Use a sharp blade and let the saw move at its own pace.

I once struggled with a thick oak board. My saw kept stopping. A fresh blade fixed it right away!

How can I tell if my saw’s motor is failing?

Look for these warning signs:

✔️ Weird noises (grinding, whining, or clicking).

✔️ Less power than before.

✔️ A burning smell after short use.

✔️ Random shutdowns, even with a sharp blade.

Why does my saw stop even after I changed the blade?

If a new blade didn’t help, power might be the problem.

✔️ Corded saws: Use a thick, heavy-duty extension cord.

✔️ Cordless saws: Charge the battery fully.

✔️ Check for dust buildup—it can cause overheating.

Can a weak battery make my saw stop mid-cut?

Yes! A low or overheating battery is a big reason why cordless saws stop.

✔️ Charge it fully before cutting.

✔️ Replace old batteries—they lose power fast.

✔️ Let hot batteries cool before using them again.

Is it safe to use a saw that keeps stopping?

No, it’s not safe. A stalling saw can kick back, burn out, or make rough cuts. Fix the issue before using it again.

✔️ Check the blade.

✔️ Test the power supply.

✔️ Look for wood pinching the blade.

✔️ Clean out dust and debris.

Conclusion

If your circular saw stops mid-cut, don’t worry! Now you know why—and how to fix it. A dull blade, weak power, pushing too hard, or overheating can all cause problems. But the good news? These are easy to fix!

Keep your blade sharp, use steady pressure, check your power source, and support your material. A little care keeps your saw running smoothly and prevents those frustrating stops.

Hi, I’m Tom Scalisi, and welcome to The Saw Blog! I started this blog to share my hands-on experience and insights about woodworking tools—especially saws and saw blades. Over the years, I’ve had the chance to work with a wide range of tools, and I’m here to help both professionals and hobbyists make informed decisions when it comes to selecting and using their equipment. Whether you’re looking for in-depth reviews, tips, or just advice on how to get the best performance out of your tools, you’ll find it here. I’m excited to be part of your woodworking journey!