What is the best way to measure a band saw blade? The most accurate method involves cutting the old blade, laying it flat, and measuring its length using a measuring tape or ruler. This article will guide you through various techniques for accurate band saw blade measuring and help you avoid costly errors.

Image Source: www.detroitbandsaw.com

Why Accurate Band Saw Blade Measurement Matters

Choosing the correct band saw blade size is crucial for several reasons. Using the wrong size can lead to:

- Damage to your band saw: An incorrect blade length can overstress the tensioning mechanism, leading to premature wear or even breakage.

- Poor cutting performance: A blade that’s too loose will wander and vibrate, resulting in inaccurate cuts and a rough finish. A blade that’s too tight can bind and overheat, reducing its lifespan.

- Safety hazards: A poorly fitted blade is more likely to break during operation, posing a risk of injury.

- Wasted money: Buying the wrong size means you have to purchase another blade, increasing your costs.

Band Saw Blade Size Guide: Key Dimensions

Before diving into the measurement techniques, it’s helpful to understand the key dimensions of a band saw blade. The three key parameters are:

- Length: This is the overall circumference of the blade, determining if it fits your band saw.

- Width: This dimension affects the blade’s ability to cut curves and its overall stability. Narrower blades are better for tight curves, while wider blades are more suitable for straight cuts.

- Thickness (Gauge): The thickness influences the blade’s durability and resistance to bending. Thicker blades are more robust but may require more power to operate.

- Teeth Per Inch (TPI): This determines the smoothness and speed of the cut. Higher TPI blades are better for fine work, while lower TPI blades are faster for thicker materials.

Methods for Band Saw Blade Measuring

There are a few different ways to figure out the right blade length for your band saw. Each method has its good and bad points, so the best one to use really depends on your situation. It mostly comes down to whether you still have the old blade to look at, or if you need to calculate the size from scratch.

Method 1: Measuring an Existing (Old) Band Saw Blade

This is the most accurate method, especially when replacing a worn or broken blade.

Step-by-Step Guide for Measuring a Used Band Saw Blade

- Remove the Old Blade: Carefully remove the old blade from your band saw. Remember to wear gloves to protect your hands from sharp edges.

- Cut the Blade (If Necessary): If the blade is still intact, you’ll need to cut it open to measure its full length. Use a pair of heavy-duty wire cutters or a metal-cutting saw.

- Lay the Blade Flat: Place the cut blade on a flat, stable surface like a workbench or the floor.

- Measure the Length: Use a measuring tape or ruler to measure the distance from one end of the blade to the other. Ensure the blade is straight and not stretched or compressed.

- Record the Measurement: Note the measurement in inches or millimeters. This is the band saw blade length you’ll need to purchase a replacement.

Tips for Accurate Band Saw Blade Measurement with an Old Blade

- Use a flexible measuring tape: A flexible tape measure will conform to any slight curves or bends in the blade.

- Measure multiple times: Take several measurements and average them to minimize errors.

- Check for wear and tear: If the blade is severely worn or damaged, the measurement might not be accurate. In this case, consider using another method.

Method 2: Using a Band Saw Blade Size Guide or Chart

Many band saw manufacturers provide size guides or charts that list the correct blade length for specific models.

How to Use a Band Saw Blade Size Guide

- Identify Your Band Saw Model: Locate the model number of your band saw. This information is usually found on a sticker or plate attached to the machine’s frame.

- Consult the Manufacturer’s Website or Manual: Visit the manufacturer’s website or refer to your band saw’s manual. Look for a section on blade replacement or specifications.

- Find the Recommended Blade Length: Locate your model number in the size guide or chart and note the corresponding blade length.

Example of a Band Saw Blade Size Chart

| Band Saw Model | Blade Length (inches) | Blade Width (inches) |

|---|---|---|

| Model A | 72 | 1/4 |

| Model B | 93.5 | 3/8 |

| Model C | 105 | 1/2 |

Advantages and Disadvantages of Using a Size Guide

- Advantages: Quick, easy, and reliable if the information is accurate.

- Disadvantages: May not be available for older or less common models. The guide might be incorrect or outdated.

Method 3: Measuring the Band Saw’s Wheel Circumference

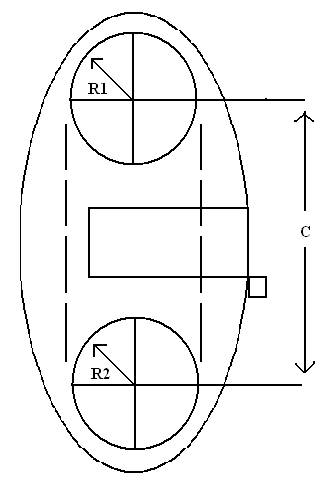

This method involves measuring the circumference of the band saw’s wheels and using a formula to estimate the blade length.

Calculating Band Saw Blade Circumference

- Measure the Wheel Diameter: Measure the diameter of one of the band saw’s wheels.

- Calculate the Circumference: Use the formula: Circumference = π (pi) * Diameter (π ≈ 3.14159).

- Estimate Blade Length: Multiply the wheel circumference by 2 (since there are two wheels) and add an allowance for blade overlap and tensioning. This allowance typically ranges from 2 to 4 inches.

- Estimated Blade Length = (2 * Wheel Circumference) + Allowance

Example Calculation

- Wheel Diameter = 12 inches

- Wheel Circumference = 3.14159 * 12 inches = 37.7 inches

- Estimated Blade Length = (2 * 37.7 inches) + 3 inches = 78.4 inches

Accuracy Considerations for this method

This method provides an estimate, but it may not be perfectly accurate due to variations in wheel size, blade tensioning mechanisms, and the allowance factor. Always double-check the estimated length against other sources if possible.

Method 4: Using a String or Cable to Measure Band Saw Blade Length

This method can be useful when you don’t have an old blade or a reliable size guide.

Using String/Cable to Find Band Saw Blade Size

- Unplug the band saw: Ensure the band saw is disconnected from the power source for safety.

- Thread a string or flexible cable: Carefully thread a non-stretchable string or cable around the two wheels of the band saw, following the path the blade would take. Make sure the string is taut and runs smoothly around the wheels.

- Mark the overlap: Mark the point where the string overlaps with itself. This will be the total length needed for the blade.

- Measure the string: Remove the string and lay it straight on a flat surface. Use a measuring tape to measure the distance from the end of the string to the marked point. This measurement represents the approximate band saw blade length required.

Tips for Accuracy with a String or Cable

- Use a non-stretchable material: Avoid using stretchy strings or elastic cords, as they will distort the measurement. Opt for a thin, non-stretchable cable or a sturdy string.

- Ensure proper tension: Keep the string taut while threading it around the wheels to accurately simulate the blade path.

- Account for blade guides: When threading the string, make sure it passes through the blade guides as it would with a real blade. This ensures the measurement is as accurate as possible.

- Double-check the measurement: Repeat the process a few times to ensure consistent results. Slight variations can occur, so taking multiple measurements can help identify the most accurate length.

Factors That Affect Band Saw Blade Dimensions

Several factors can influence the correct band saw blade dimensions for your machine:

- Band Saw Model: Different band saw models require different blade lengths, widths, and thicknesses.

- Wheel Diameter: The size of the band saw wheels directly affects the required blade length.

- Tensioning Mechanism: The type and range of the tensioning mechanism can influence the optimal blade length.

- Blade Material: Different blade materials (e.g., carbon steel, bi-metal) may have slightly different stretching properties, which can affect the required length.

- Cutting Application: The type of material you’re cutting (e.g., wood, metal) and the desired cut quality can influence the ideal blade width and TPI.

Common Mistakes to Avoid During Band Saw Blade Measuring

- Using a stretched or damaged blade: A worn-out blade can give you an inaccurate measurement.

- Measuring in the wrong units: Ensure you’re measuring in the same units (inches or millimeters) as the replacement blade.

- Ignoring the blade width and thickness: These dimensions are as important as the length for proper fit and performance.

- Assuming all blades are the same size: Even similar-looking band saws can require different blade sizes.

- Overlooking the tooth configuration (TPI): Choosing the wrong TPI can lead to poor cutting performance.

- Forgetting to unplug the band saw during measurement: This is a crucial safety precaution.

- Not consulting the manufacturer’s guide: Always check the manufacturer’s specifications for the recommended blade size.

Troubleshooting Common Band Saw Blade Problems

Even with accurate measurement, you might encounter issues with your band saw blade. Here are some common problems and their solutions:

- Blade breaks frequently: This could be due to excessive tension, a dull blade, or using the wrong blade for the material.

- Blade wanders or drifts: This can be caused by insufficient tension, a dull blade, or improper blade alignment.

- Blade makes rough cuts: This could be due to a dull blade, incorrect TPI, or excessive feed rate.

- Blade slips off the wheels: This is usually a sign of insufficient tension or worn tires on the wheels.

- Blade vibrates excessively: This could be caused by a loose blade, damaged wheels, or an unbalanced machine.

Buying a Band Saw Blade Replacement Size: Where to Purchase

Once you have the correct measurements, you can purchase a replacement band saw blade from various sources:

- Online Retailers: Amazon, eBay, and other online retailers offer a wide selection of band saw blades.

- Hardware Stores: Local hardware stores typically stock a range of common blade sizes.

- Specialty Tool Stores: These stores often carry a more extensive selection of high-quality blades.

- Band Saw Manufacturers: You can purchase blades directly from the manufacturer of your band saw.

When buying a blade, consider the following:

- Blade Material: Choose a material appropriate for the materials you’ll be cutting.

- Blade Width: Select a width that suits the types of cuts you’ll be making (straight or curved).

- TPI: Choose a TPI that provides the desired cut quality and speed.

- Brand Reputation: Opt for reputable brands known for quality and durability.

- Customer Reviews: Read reviews from other users to get an idea of the blade’s performance.

Fathoming Band Saw Blade Materials

Band saw blades are made from various materials, each offering different strengths and weaknesses. Here’s a brief overview:

- Carbon Steel: Economical and suitable for general-purpose woodworking.

- High-Speed Steel (HSS): More durable than carbon steel and can withstand higher temperatures, making them suitable for cutting harder woods and some metals.

- Bi-Metal: Combine a high-speed steel cutting edge with a flexible carbon steel back, offering excellent durability and versatility for cutting a wide range of materials.

- Carbide-Tipped: The most durable and expensive type of blade, ideal for cutting abrasive materials like fiberglass, composites, and hardened metals.

Choosing the right blade material depends on your budget, the materials you’ll be cutting, and the desired blade lifespan.

Interpreting Band Saw Blade Tooth Geometry

The tooth geometry of a band saw blade refers to the shape, angle, and arrangement of the teeth. Different tooth geometries are designed for specific cutting applications. Here are some common types:

- Standard Teeth: General-purpose teeth suitable for cutting a variety of materials.

- Skip Teeth: Teeth with a large gullet (the space between teeth) for efficient chip removal when cutting soft materials like wood.

- Hook Teeth: Teeth with a positive rake angle for aggressive cutting of thicker materials.

- Variable Pitch Teeth: Teeth with varying spacing to reduce vibration and noise when cutting metal.

Selecting the appropriate tooth geometry can significantly improve cutting performance and blade life.

FAQ: Accurately Measuring Band Saw Blades

-

What if I can’t find my band saw model in the size guide?

If you cannot locate your model in the size guide, try contacting the manufacturer directly or consulting online forums and communities dedicated to band saws. Someone may have experience with your specific model and can provide the correct blade length. -

Can I use a blade that’s slightly longer or shorter than the recommended size?

While minor variations (within 1/2 inch) might work, it’s generally not recommended. A blade that’s too long may not tension properly, leading to slippage and poor cutting. A blade that’s too short may overstress the tensioning mechanism and could break. Always aim for the exact recommended size. -

How often should I replace my band saw blade?

The frequency of blade replacement depends on factors like the type of materials you cut, the frequency of use, and the quality of the blade. Replace the blade when it becomes dull, starts to wander, or shows signs of damage.

- What tools do I need for band saw blade replacement?

You’ll typically need a pair of gloves, a wrench or Allen key to loosen the blade tension, wire cutters (if you need to cut the old blade), and a measuring tape.

- Are all band saw blades the same width?

No, band saw blades come in various widths. The appropriate width depends on the type of cuts you’ll be making. Narrower blades are better for curves, while wider blades are better for straight cuts.

- What is TPI and why is it important?

TPI stands for Teeth Per Inch. It refers to the number of teeth on the blade per inch of length. Higher TPI blades are better for fine cuts, while lower TPI blades are better for fast cuts in thicker materials.

By following these guidelines and understanding the factors that affect band saw blade size, you can ensure accurate measurements, avoid costly errors, and enjoy optimal cutting performance.

Hi, I’m Tom Scalisi, and welcome to The Saw Blog! I started this blog to share my hands-on experience and insights about woodworking tools—especially saws and saw blades. Over the years, I’ve had the chance to work with a wide range of tools, and I’m here to help both professionals and hobbyists make informed decisions when it comes to selecting and using their equipment. Whether you’re looking for in-depth reviews, tips, or just advice on how to get the best performance out of your tools, you’ll find it here. I’m excited to be part of your woodworking journey!