What is the best way to measure a band saw blade? The best way depends on whether you have the old blade or not. If you have the old blade, measure its length directly. If not, measure the band saw itself using a flexible measuring tape or a string, then consult the manufacturer’s specifications. Getting the correct band saw blade length is crucial for optimal performance and safety. This bandsaw blade measuring guide will help you achieve an accurate bandsaw blade measurement every time.

Image Source: www.detroitbandsaw.com

Why Correct Band Saw Blade Length Matters

A band saw blade size that’s even slightly off can cause several problems:

- Poor Cutting Performance: A loose blade will wander and produce inaccurate cuts.

- Blade Slippage: An incorrectly sized blade might slip off the wheels, posing a safety hazard.

- Increased Wear and Tear: A blade that’s too tight can put excessive stress on the saw’s components, leading to premature failure.

- Difficulty Tracking: Getting the blade to stay on the wheels and track straight becomes a constant struggle.

- Machine Damage: In severe cases, an incorrect blade can damage the band saw itself.

Ultimately, finding the right bandsaw blade length ensures smooth, accurate cuts and prolongs the life of both the blade and the machine. It’s a critical step in bandsaw blade replacement size selection.

Methods for Bandsaw Blade Measuring Guide

There are several methods to accurately measure for a band saw blade. Choose the method that best fits your situation:

1. Measuring the Old Blade

This is the easiest and most reliable method, provided the old blade is still intact.

Steps:

- Lay the Blade Flat: Place the old blade on a flat surface.

- Use a Measuring Tape: Use a flexible measuring tape to measure the blade’s entire length. Make sure the tape follows the blade’s curve.

- Accurate Measurement: For the most accurate measurement, use a specialized blade measuring tool, but a tape measure will work in most cases.

- Record the Measurement: Note the length in inches. This is the band saw blade length you need.

Table: Example Measurements

| Blade Type | Measured Length (Inches) |

|---|---|

| Small Benchtop Saw | 56 1/8 |

| 14-inch Band Saw | 93 1/2 |

| Large Industrial Saw | 156 |

Measuring Used Bandsaw Blade Considerations:

- Check for Stretching: Used bandsaw blades can stretch over time. If the old blade appears noticeably longer than it used to, it’s best to confirm the measurement with another method or consult your saw’s manual.

- Damage Assessment: Inspect the old blade for any breaks or significant damage. If the blade is severely damaged, the measurement might not be accurate.

2. Measuring the Band Saw Directly

If you don’t have the old blade, you’ll need to measure the band saw itself. This method requires a flexible measuring tape or a piece of string. This is an alternative bandsaw blade measuring guide.

Steps:

- Unplug the Saw: For safety, always unplug the band saw before making any measurements.

- Open the Blade Guides: Open the upper and lower blade guides to their widest setting. This provides enough space to maneuver the measuring tape or string.

- Wrap the Tape/String: Carefully wrap the flexible measuring tape (or string) around the wheels, following the path the blade would take. Ensure the tape/string sits snugly in the wheel grooves.

- Mark the Overlap: If using string, mark the point where the string overlaps.

- Measure the Length: Measure the string from the starting point to the mark. If using a measuring tape, note the final reading.

- Consult the Manual: Compare your measurement to the band saw blade length specified in your band saw’s manual. This is a crucial step to confirm accuracy.

Things to Remember:

- Tension Adjustment: This method estimates the length with the blade tension set to zero. Slight variations might occur when the blade is tensioned.

- Wheel Alignment: Ensure the wheels are properly aligned before measuring. Misaligned wheels can affect the accuracy of the measurement.

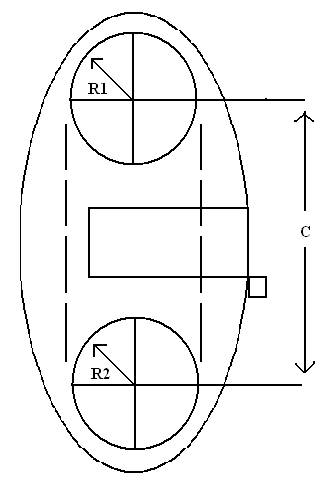

3. Calculating Bandsaw Blade Circumference Using Wheel Diameter

This method uses the diameter of your band saw’s wheels to calculate bandsaw blade circumference. It’s less precise than the other two but can be helpful for a rough estimate.

Formula:

- Circumference = π (pi) * Diameter

Steps:

- Measure the Wheel Diameter: Measure the diameter of one of your band saw’s wheels. The diameter is the distance across the wheel, passing through the center.

- Apply the Formula: Multiply the diameter by π (approximately 3.14159).

- Multiply by Two: Since the blade travels around two wheels, multiply the result by two to approximate the required blade length.

- Account for Tension: Add a small amount (typically 1-2 inches) to account for blade tension.

Example:

- Wheel Diameter: 14 inches

- Circumference of one wheel: 14 * 3.14159 = 43.98 inches

- Total Length (two wheels): 43.98 * 2 = 87.96 inches

- Adjusted Length (for tension): 87.96 + 2 = 89.96 inches (approximately 90 inches)

Limitations:

- Approximation: This method provides an estimate, not an exact measurement.

- Ignores Blade Guides: It doesn’t account for the length of the blade between the wheels due to the blade guides.

4. Checking the Manufacturer’s Specifications

The most reliable way to determine bandsaw blade size is to consult your band saw’s manual or the manufacturer’s website.

Steps:

- Identify Your Saw’s Model: Locate the model number of your band saw. This is usually found on a sticker or plate on the machine.

- Find the Manual: Search for the manual online using the model number. Most manufacturers provide digital copies of their manuals.

- Look for Blade Specifications: The manual will specify the correct band saw blade length, width, and thickness for your saw.

- Verify Information: Cross-reference the information with other sources, such as online forums or reviews, to ensure accuracy.

Why This is Important:

- Guaranteed Compatibility: Using the manufacturer’s recommended blade size ensures proper fit and optimal performance.

- Avoid Damage: Incorrect blade sizes can damage the saw or lead to unsafe operating conditions.

Bandsaw Blade Measurement Tutorial: Step-by-Step Guide

Let’s go through a detailed tutorial on measuring a band saw blade:

Scenario: You have a 14-inch band saw, and you need to replace the blade, but you don’t have the old one.

Tools Needed:

- Flexible measuring tape

- Pencil and paper

- Band saw manual (optional)

Steps:

- Safety First: Unplug the band saw from the power outlet.

- Open Blade Guides: Open the upper and lower blade guides to their widest setting.

- Wrap the Measuring Tape: Start at one point on the upper wheel and carefully wrap the measuring tape around the wheel, following the groove where the blade sits.

- Continue to the Lower Wheel: Continue wrapping the tape down to the lower wheel, ensuring it follows the correct path.

- Complete the Circuit: Bring the tape back up to the starting point on the upper wheel.

- Record the Measurement: Note the total length of the measuring tape. Let’s say it measures 93.5 inches.

- Consult the Manual: Check your band saw’s manual to confirm the recommended blade length for your 14-inch saw. The manual should state that a 93 1/2 inch blade is correct.

- Verify: If you don’t have the manual, search online for “14-inch band saw blade length” to find the standard size.

- Order the Correct Blade: Order a bandsaw blade replacement size of 93 1/2 inches.

Tips for Accuracy:

- Ensure the measuring tape is snug against the wheels but not stretched.

- Double-check the measurement to avoid errors.

- If possible, have someone assist you to hold the tape in place.

Choosing the Right Blade Width and Thickness

While band saw blade length is the primary concern, blade width and thickness also play a significant role in performance.

Blade Width:

- Wider Blades: Wider blades are better for straight cuts and resawing because they resist bending.

- Narrower Blades: Narrower blades are better for cutting curves and intricate shapes because they can navigate tighter radii.

Blade Thickness (Gauge):

- Thicker Blades: Thicker blades are more durable and can withstand higher tension, but they require more power.

- Thinner Blades: Thinner blades are more flexible and require less power, but they are more prone to breaking.

General Guidelines:

- For general-purpose cutting: A 1/4-inch to 3/8-inch blade is a good choice.

- For cutting curves: A 1/8-inch or 3/16-inch blade is recommended.

- For resawing: A 1/2-inch or 3/4-inch blade is ideal.

Safety Precautions

- Always unplug the band saw before making any adjustments or measurements.

- Wear safety glasses to protect your eyes from debris.

- Use caution when handling sharp blades.

- Make sure the blade is properly tensioned before operating the saw.

- Never operate the saw with loose or damaged parts.

Troubleshooting

Problem: The new blade is slightly too short.

Solution:

First, go ahead and double-check your measurements. You also want to make sure the blade tension is set correctly. If the blade turns out to be just a tiny bit short, you might be able to shift the wheels enough to make it fit. Just be careful—if you try to force a blade that is truly too short, you could end up damaging your saw.

Problem: The new blade is slightly too long.

Solution: A blade that’s too long will likely slip off the wheels. Ensure the blade tensioning mechanism is working correctly. If the blade is significantly too long, you’ll need to exchange it for the correct size.

Problem: The blade keeps slipping off the wheels.

Solution: Check the wheel alignment. Ensure the blade is properly tensioned. The blade guides might be worn or improperly adjusted.

Frequently Asked Questions (FAQ)

How often should I replace my band saw blade?

- Replace the blade when it becomes dull, damaged, or starts to produce poor-quality cuts. The frequency depends on usage and the materials being cut.

Can I use a longer or shorter blade than the manufacturer recommends?

- It’s generally not recommended. Using an incorrect blade length can lead to poor performance, blade slippage, and potential damage to the saw.

What is blade tension, and why is it important?

- Blade tension is the amount of force applied to the blade to keep it taut. Proper tension is crucial for accurate cuts and preventing blade slippage.

How do I tension a band saw blade?

- Consult your band saw’s manual for specific instructions on how to tension the blade. Typically, there’s a tensioning knob or lever that adjusts the upper wheel’s position.

What is blade drift, and how can I prevent it?

- Blade drift is when the blade veers off course during a cut. It can be caused by a dull blade, improper tension, or misalignment. Use a sharp blade, proper tension and ensure the saw is correctly aligned.

Can I weld a broken band saw blade?

- Yes, you can weld a broken band saw blade, but it requires specialized equipment and skills. It’s often more cost-effective to purchase a new blade.

By following this comprehensive bandsaw blade measuring guide, you can ensure you always have the correct band saw blade length for your machine, leading to safer operation and better cutting performance. Remember to prioritize safety and consult your band saw’s manual for specific instructions and recommendations. Accurate bandsaw blade measurement is the key to unlocking the full potential of your band saw.

Hi, I’m Tom Scalisi, and welcome to The Saw Blog! I started this blog to share my hands-on experience and insights about woodworking tools—especially saws and saw blades. Over the years, I’ve had the chance to work with a wide range of tools, and I’m here to help both professionals and hobbyists make informed decisions when it comes to selecting and using their equipment. Whether you’re looking for in-depth reviews, tips, or just advice on how to get the best performance out of your tools, you’ll find it here. I’m excited to be part of your woodworking journey!