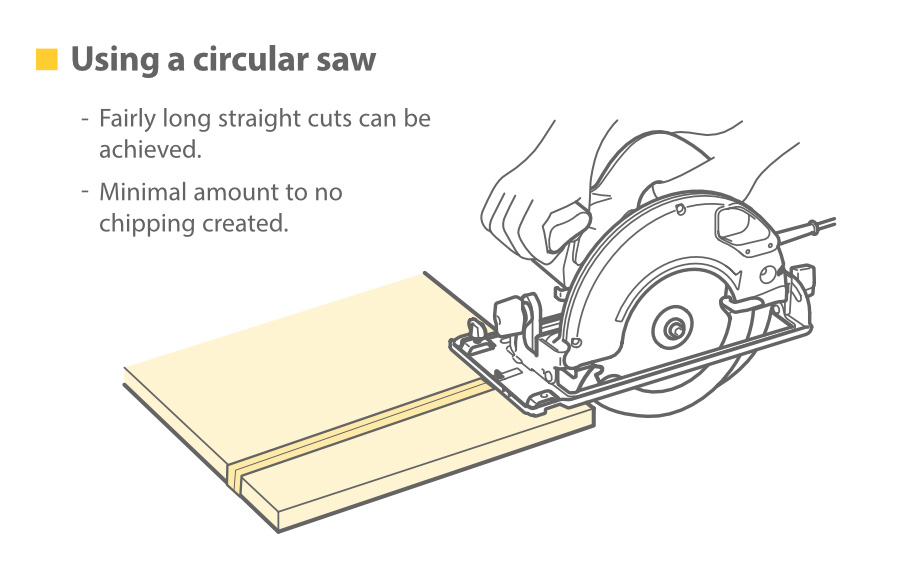

Can I cut melamine with a circular saw? Yes, you can! But you need the right tools and skills. This guide will show you how to cut melamine with a circular saw and avoid chipping. Get ready for clean, professional-looking cuts.

Image Source: www.wardrobedoorsdirect.co.uk

The Challenge: Why Melamine Chips

Melamine is a pretty tough material, but it’s also very brittle. It’s basically just a thin layer of decorative paper glued onto a core made of compressed wood. The problem is that when you try to cut it, the saw blade can easily rip that top paper layer, leaving you with ugly chips and splinters along the edge. The secret to getting a good cut is doing everything you can to stop that tearing from happening. This guide will show you the best tricks for cutting melamine so it looks clean and professional.

Essential Tools and Preparation

Before you start, gather the right tools.

The Right Circular Saw Blade for Melamine

A standard wood-cutting blade will likely cause significant chipping. The best choice is a high-tooth-count blade designed for laminates or melamine. These blades have a special grind that slices through the material cleanly.

- Tooth Count: Look for blades with 60 teeth or more for a 10-inch blade. A higher tooth count supports fine cutting.

- Tooth Grind: A Triple Chip Grind (TCG) is ideal. TCG blades have a flat-topped tooth that does most of the cutting, followed by a beveled tooth that cleans up the edge.

- Blade Material: Carbide-tipped blades stay sharp longer than steel blades, making them a better investment.

Here’s a quick comparison:

| Blade Type | Tooth Count | Tooth Grind | Performance on Melamine |

|---|---|---|---|

| Standard Wood Blade | 24-40 | ATB | High Chipping |

| Laminate/Melamine | 60+ | TCG | Minimal Chipping |

| Fine-Cut Plywood | 40-80 | ATB | Moderate Chipping |

Other Must-Have Tools

- Circular Saw: A well-maintained circular saw with a stable base.

- Clamps: To secure the melamine sheet to your work surface.

- Straight Edge: A metal ruler or guide rail for accurate cuts.

- Masking Tape: Wide painter’s tape to further prevent chipping.

- Scoring Knife or Utility Knife: For pre-scoring the cut line.

- Safety Glasses: Protect your eyes from flying debris.

- Dust Mask: Melamine dust can be harmful to breathe.

- Hearing Protection: Circular saws are loud.

- Work Table: A stable surface to work on.

Melamine Cutting Techniques: Step-by-Step

Follow these steps for clean cuts. This is the best way to cut melamine board.

1. Preparing the Melamine Sheet

- Clean the Surface: Wipe down the melamine with a clean cloth to remove dust and debris.

- Mark the Cut Line: Use a pencil to mark the desired cut line. Measure carefully and double-check your measurements.

- Apply Masking Tape: Apply two layers of wide painter’s tape along the cut line on both sides of the melamine sheet. The tape acts as a barrier to prevent chipping and splintering.

2. Scoring Melamine Before Cutting

Scoring the melamine before cutting is a critical step to prevent chipping. Use a sharp scoring knife or utility knife.

- Score Along the Cut Line: Carefully score along the marked cut line, pressing firmly enough to cut through the melamine’s surface layer. Make multiple passes for a deeper score.

- The Purpose of Scoring: Scoring weakens the surface layer of the melamine, creating a clean starting point for the saw blade. This minimizes tear-out and chipping.

3. Setting Up Your Circular Saw

- Install the Blade: Install the high-tooth-count melamine blade into your circular saw. Make sure the blade is securely tightened.

- Adjust the Blade Depth: Adjust the blade depth so that it extends just slightly beyond the thickness of the melamine sheet (about ¼ inch). Too much blade exposure can increase the risk of chipping.

- Test Cut (Optional): Make a test cut on a scrap piece of melamine to ensure your setup is correct and to get a feel for how the blade is cutting.

4. Cutting Melamine with a Circular Saw

- Secure the Melamine: Place the melamine sheet on your work table with the finished side facing up. Secure the sheet with clamps to prevent it from moving during the cut. Ensure the cut line is fully supported.

- Use a Straight Edge: Position a straight edge (metal ruler or guide rail) along the cut line. This will guide your circular saw and ensure a straight, accurate cut.

- Start the Cut: Turn on the circular saw and let it reach full speed before contacting the melamine.

- Feed the Saw Slowly and Steadily: Guide the saw along the straight edge, applying consistent pressure. Avoid forcing the saw or stopping mid-cut, as this can cause chipping.

- Support the Offcut: As you cut, support the offcut (the piece being removed) to prevent it from sagging and causing tear-out.

- Complete the Cut: Continue cutting until you have completely separated the two pieces.

5. Post-Cut Cleanup

- Remove the Tape: Carefully peel off the masking tape.

- Inspect the Cut Edge: Check the cut edge for any minor chipping or splintering.

- Sand Lightly (If Needed): If there are any small imperfections, lightly sand the edge with fine-grit sandpaper (220 grit or higher). Be careful not to damage the melamine surface.

Minimizing Chipping: Extra Tips

Here are some extra circular saw tips for melamine to ensure clean cuts:

- Use a Zero-Clearance Insert: A zero-clearance insert for your circular saw minimizes the gap around the blade, providing more support to the melamine and reducing chipping.

- Consider a Down-Cutting Blade: Some specialty blades are designed to cut downwards, pushing the melamine fibers into the core rather than pulling them out.

- Try a Router: For very precise cuts or intricate shapes, a router with a laminate trimming bit can produce excellent results.

- Sharp Blades are Key: A dull blade is more likely to cause chipping. Regularly sharpen or replace your blade.

- Reduce Vibration: Ensure your saw is stable and properly adjusted to minimize vibration, which can contribute to chipping.

Alternative Cutting Methods

While a circular saw is a common choice, other tools can also cut melamine.

- Table Saw: A table saw, with the right blade and technique, can produce very clean cuts in melamine. Use a zero-clearance insert and a sharp blade.

- Panel Saw: Panel saws are specifically designed for cutting large sheets of material like melamine. They offer excellent precision and support.

- Jigsaw: A jigsaw can cut curves and intricate shapes in melamine, but it is more prone to chipping than a circular saw or table saw. Use a fine-tooth blade and apply masking tape.

- CNC Router: A CNC router offers the highest level of precision and can cut complex shapes in melamine with minimal chipping.

Troubleshooting: Common Problems and Solutions

| Problem | Possible Cause | Solution |

|---|---|---|

| Excessive Chipping | Dull blade, incorrect blade type, fast feed rate | Replace blade, use a laminate blade, slow down the cutting speed |

| Splintering | Not scoring the melamine, blade depth too high | Score the melamine before cutting, adjust blade depth |

| Uneven Cut | Unstable saw, no straight edge | Use a stable saw, use a straight edge or guide rail |

| Burning | Dull blade, slow feed rate | Replace blade, increase the cutting speed |

| Blade binding | Incorrect blade depth, material not supported | Adjust blade depth, support the material on both sides of the cut |

Professional Melamine Cutting

Achieving truly professional results often involves specialized equipment and techniques. Cabinet makers and furniture manufacturers may use:

- Edgebanders: These machines apply edge banding to melamine edges, creating a seamless and durable finish.

- Beam Saws: Large, automated saws that can cut multiple sheets of melamine at once with extreme precision.

- Optimizing Software: Software that calculates the most efficient cutting patterns to minimize waste and maximize material yield.

However, with the right tools and techniques, you can achieve excellent results with a circular saw in your own workshop. This article describes clean cuts in melamine.

Safety First

Always prioritize safety when working with power tools.

- Wear safety glasses, a dust mask, and hearing protection.

- Work in a well-ventilated area.

- Keep your work area clean and free of clutter.

- Disconnect the power cord before changing blades or making adjustments.

- Never force the saw. Let the blade do the work.

- If you are not comfortable using a circular saw, seek professional assistance.

FAQ: Cutting Melamine

Here are some frequently asked questions about cutting melamine without splintering.

Q: What is the best blade for cutting melamine?

A: The best blade is a high-tooth-count blade (60+ teeth for a 10-inch blade) specifically designed for laminates or melamine. Look for a Triple Chip Grind (TCG) blade.

Q: Can I use a regular wood blade to cut melamine?

A: While you can, it’s not recommended. A regular wood blade will likely cause significant chipping and splintering.

Q: Do I need to score melamine before cutting?

A: Yes, scoring is highly recommended. It helps to prevent chipping by creating a clean starting point for the saw blade.

Q: What is a zero-clearance insert and why should I use one?

A: A zero-clearance insert is a replacement insert for your circular saw that has a very small gap around the blade. This provides more support to the melamine and reduces chipping.

Q: How can I prevent the melamine from moving while I’m cutting?

A: Use clamps to secure the melamine sheet to your work surface.

Q: What should I do if I get some minor chipping?

A: Lightly sand the edge with fine-grit sandpaper (220 grit or higher).

Q: Is it better to cut melamine with the finished side up or down?

A: It’s generally recommended to cut with the finished side up. This is because most circular saws cut on the upstroke, which can cause tear-out on the bottom surface.

Q: What if I don’t have a scoring knife?

A: You can use a sharp utility knife or even a specialized scoring tool designed for laminates.

By following these melamine cutting techniques and tips, you can achieve clean, professional-looking cuts in melamine with a circular saw and avoid frustrating chipping.

Hi, I’m Tom Scalisi, and welcome to The Saw Blog! I started this blog to share my hands-on experience and insights about woodworking tools—especially saws and saw blades. Over the years, I’ve had the chance to work with a wide range of tools, and I’m here to help both professionals and hobbyists make informed decisions when it comes to selecting and using their equipment. Whether you’re looking for in-depth reviews, tips, or just advice on how to get the best performance out of your tools, you’ll find it here. I’m excited to be part of your woodworking journey!