A miter saw table is a vital addition to any workshop, offering a stable and accurate platform for your miter saw. But what is a miter saw table? It’s essentially a dedicated workstation designed to improve the efficiency and precision of your cuts. It can be a simple stand or a complex setup with features like outfeed support, dust collection, and storage. This guide will provide comprehensive miter saw station plans and essential information to help you build your own, from basic DIY miter saw stand to more advanced miter saw workstation.

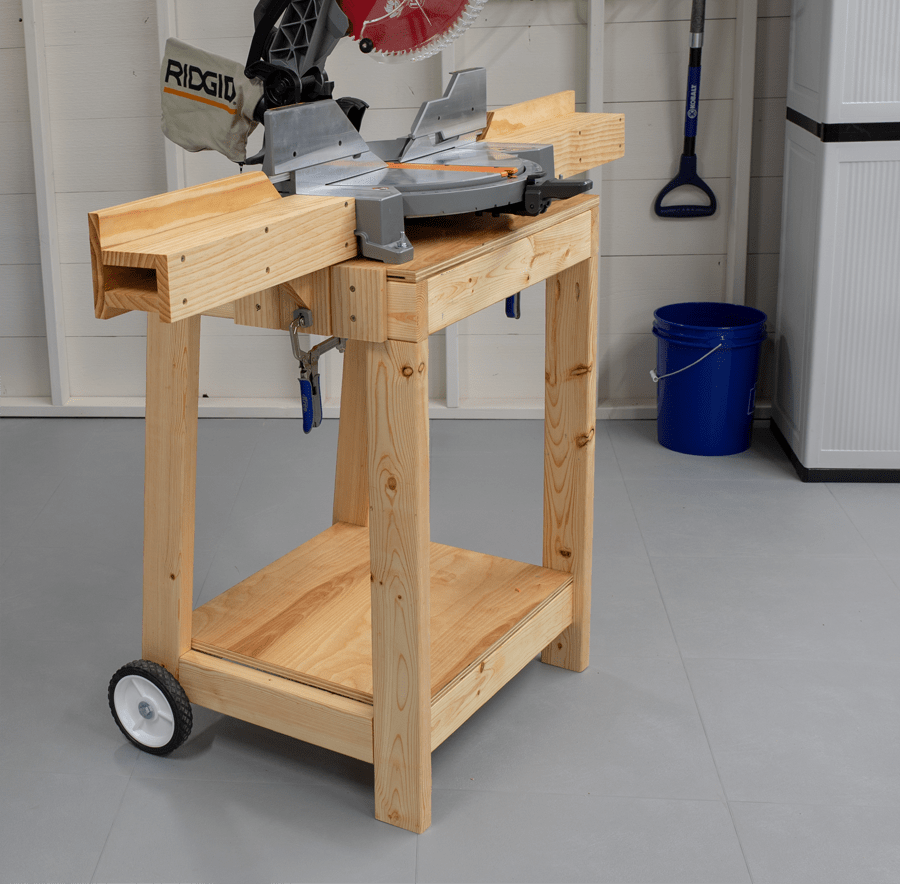

Image Source: learn.kregtool.com

Why Build a Miter Saw Table?

A miter saw table offers numerous benefits for both hobbyist woodworkers and professionals. Here’s why you should consider building one:

- Improved Accuracy: A stable and level surface minimizes vibrations and ensures accurate cuts.

- Enhanced Safety: A secure platform prevents the saw from moving during operation, reducing the risk of accidents.

- Increased Efficiency: A well-designed table streamlines your workflow by providing convenient access to tools and materials.

- Dust Control: Integrated dust collection systems can significantly reduce airborne dust, creating a cleaner and healthier work environment.

- Better Material Support: Outfeed support for miter saw helps handle long pieces of wood, preventing sagging and ensuring precise cuts.

- Organized Workspace: Miter saw table storage keeps your tools and accessories within easy reach, maximizing efficiency and minimizing clutter.

Planning Your Miter Saw Table

Before you start building, careful planning is crucial. Here are some key considerations:

Determine Your Needs

Think about your typical projects, available space, and desired features. Do you need a portable miter saw table for job sites, or a stationary workstation for your garage? Do you prioritize miter saw table with dust collection or extensive miter saw table storage?

Assess Your Space

Measure your available workspace to determine the maximum miter saw table dimensions. Consider the required clearance for operating the saw and maneuvering materials.

Decide on Features

Consider these features:

- Outfeed Support: Essential for handling long boards.

- Dust Collection: Improves air quality and reduces cleanup.

- Storage: Drawers, shelves, and cabinets for tools and materials.

- Mobility: Wheels or casters for easy relocation.

- Adjustable Height: Allows for comfortable operation for different users.

Choosing the Right Materials

Common materials for building a miter saw table include:

- Plywood: A strong and affordable option for the table top and frame.

- Solid Wood: Provides a durable and aesthetically pleasing surface.

- 2×4 Lumber: Ideal for building the frame and supports.

- MDF (Medium-Density Fiberboard): A smooth and stable option for the table top.

Pros and Cons of Different Materials

| Material | Pros | Cons |

|---|---|---|

| Plywood | Strong, affordable, readily available. | Can splinter, may require finishing. |

| Solid Wood | Durable, aesthetically pleasing. | More expensive, can warp or twist. |

| 2×4 Lumber | Strong, inexpensive, easy to work with. | Can be rough, may require planing. |

| MDF | Smooth, stable, easy to paint. | Less durable than plywood, susceptible to moisture damage. |

Exploring Miter Saw Table Designs

The best miter saw table design depends on your individual needs and preferences. Here are a few popular options:

- Basic Stand: A simple platform with legs.

- Winged Table: Features extensions on either side of the saw for increased outfeed support for miter saw.

- Flip-Top Table: A versatile design that allows you to switch between a miter saw and another tool, like a planer or jointer.

- Mobile Workstation: A table with wheels for easy movement around the shop.

- Integrated System: A comprehensive miter saw workstation with built-in storage, dust collection, and other features.

Miter Saw Station Plans: Step-by-Step Guide

This section provides a detailed plan for building a basic miter saw table with outfeed support wings. These miter saw station plans can be adapted to suit your specific needs.

Materials List

- (1) 4′ x 8′ sheet of 3/4″ plywood

- (8) 2×4 lumber (8 feet long)

- (1) 2′ x 4′ sheet of 1/4″ plywood (for dust collection baffle – optional)

- Wood screws (various sizes)

- Wood glue

- T-track (for fence adjustment)

- Miter saw hold-down clamps

- Dust collection fitting (2.5″ or 4″, depending on your system – optional)

- Casters (optional)

- Finishing supplies (paint, stain, varnish)

Tools Required

- Miter saw

- Table saw (optional, but recommended for precise cuts)

- Drill/driver

- Screwdriver

- Measuring tape

- Square

- Clamps

- Safety glasses

- Hearing protection

- Dust mask

Step-by-Step Instructions

Step 1: Build the Base Frame

- Cut the 2×4 lumber to create the frame supports. A typical miter saw table dimensions would be 36″ high, 48″ wide, and 24″ deep. Adjust these measurements to suit your needs.

- Assemble the frame using wood screws and glue. Ensure the frame is square.

- Add cross braces to provide additional support and rigidity.

Step 2: Construct the Table Top

- Cut the 3/4″ plywood to the desired size for the table top (e.g., 48″ x 24″).

- Attach the table top to the base frame using wood screws and glue.

- Reinforce the connection with additional screws from underneath the frame.

Step 3: Add Outfeed Support Wings

- Cut two pieces of 3/4″ plywood to the desired size for the outfeed wings (e.g., 24″ x 24″).

- Attach the wings to the sides of the table top using hinges. This allows the wings to be folded down when not in use.

- Alternatively, you can create fixed wings by attaching them directly to the table top with screws and glue.

Step 4: Create the Miter Saw Fence

- Cut a piece of 3/4″ plywood to create the miter saw fence. The length will depend on the width of your table.

- Install T-track along the fence to allow for adjustable stops and clamps.

- Attach the fence to the table top using screws and bolts. Ensure the fence is perfectly straight and perpendicular to the miter saw blade.

- You can explore ideas for building a miter saw fence online for inspiration.

Step 5: Install Dust Collection (Optional)

- Cut a hole in the table top beneath the miter saw to accommodate the dust collection fitting.

- Attach the fitting to the underside of the table top.

- Build a simple box or baffle around the saw to direct dust into the collection port. Use the 1/4″ plywood for this.

- Connect your dust collector to the fitting.

Step 6: Add Storage (Optional)

- Design and build drawers, shelves, or cabinets to fit within the base frame.

- Use plywood or solid wood for the storage components.

- Install drawer slides for smooth operation.

Step 7: Add Mobility (Optional)

- Attach casters to the bottom of the base frame.

- Choose heavy-duty casters that can support the weight of the table and tools.

- Consider using locking casters to prevent the table from moving during operation.

Step 8: Finishing

- Sand all surfaces smooth.

- Apply a finish of your choice, such as paint, stain, or varnish.

- Allow the finish to dry completely before using the table.

Adjusting for Portable Miter Saw Table

If you need a portable miter saw table, focus on these modifications:

- Lightweight Materials: Use lighter plywood and thinner lumber to reduce weight.

- Collapsible Design: Design the table to fold up for easy transport. Consider using folding legs or hinges.

- Carry Handles: Add handles to the sides of the table for easy lifting.

- Compact Dimensions: Keep the table dimensions as small as possible while still providing adequate support.

Advanced Features: Taking Your Table to the Next Level

Once you have a basic miter saw table, you can add advanced features to further enhance its functionality.

Integrated Dust Collection

Effective miter saw table with dust collection requires careful planning. Consider these options:

- Dust Hood: A hood that surrounds the saw to capture dust at the source.

- Blast Gate: A valve that controls airflow to the dust collection port.

- Cyclone Separator: A device that separates dust from the air stream before it reaches the dust collector.

Precision Measurement Systems

For even greater accuracy, consider adding a precision measurement system to your miter saw table. Options include:

- Digital Readouts: Provide precise measurements of cut angles and lengths.

- Laser Guides: Project a laser line onto the workpiece to indicate the cut line.

- Micro-Adjustable Stops: Allow for fine-tuning of cut lengths.

Adjustable Outfeed Rollers

These rollers are adjustable in height and can be positioned to support long workpieces. They are particularly useful when cutting crown molding or other large materials.

Electrical Outlets

Integrating electrical outlets into your miter saw table provides convenient power access for your saw and other tools.

Tips for Building Success

- Take Accurate Measurements: Precise measurements are essential for a well-built table.

- Use Quality Materials: Choose high-quality materials that will withstand the rigors of regular use.

- Follow the Plans Carefully: Adhere to the miter saw station plans to ensure the table is structurally sound.

- Use Safety Equipment: Always wear safety glasses, hearing protection, and a dust mask when working with power tools.

- Take Your Time: Don’t rush the building process. Allow yourself plenty of time to complete each step carefully.

- Ask for Help: If you’re unsure about any aspect of the project, don’t hesitate to ask for help from experienced woodworkers.

- Customize to Your Needs: Modify the plans to suit your specific needs and preferences.

- Regular Maintenance: Routinely check and maintain your miter saw table to ensure it remains in good working order.

- Consult Online Resources: There are numerous online resources available, including videos and forums, that can provide helpful tips and guidance.

Troubleshooting Common Problems

- Table is Not Level: Use shims to level the table top.

- Fence is Not Square: Adjust the fence until it is perfectly perpendicular to the miter saw blade.

- Dust Collection is Ineffective: Check for leaks in the dust collection system and ensure the dust collector is powerful enough.

- Wings are Sagging: Add additional supports to the wings.

- Drawers are Sticking: Apply lubricant to the drawer slides.

FAQ

Can I build a miter saw table if I’m a beginner? Yes, absolutely! Start with a simple design and gradually add more features as your skills improve.

What is the ideal height for a miter saw table? The ideal height is typically around 36 inches, but you should adjust it to suit your own height and preferences.

Who is this project best suited for? This project is suitable for anyone with basic woodworking skills and access to the necessary tools.

What are the most important features to include? The most important features are a stable and level table top, accurate fence, and adequate outfeed support for miter saw.

Conclusion

Building your own miter saw table is a great project that makes your woodworking faster and much more precise. By following these plans and adding some key features, you’ll end up with a solid workstation that lasts for years. Just remember to keep safety first, take your time, and feel free to change the design so it works perfectly for your shop. Have fun building!

Hi, I’m Tom Scalisi, and welcome to The Saw Blog! I started this blog to share my hands-on experience and insights about woodworking tools—especially saws and saw blades. Over the years, I’ve had the chance to work with a wide range of tools, and I’m here to help both professionals and hobbyists make informed decisions when it comes to selecting and using their equipment. Whether you’re looking for in-depth reviews, tips, or just advice on how to get the best performance out of your tools, you’ll find it here. I’m excited to be part of your woodworking journey!