Ever ripped through a sheet of plywood, only to be left with a ragged, splintered mess? We’ve all been there! Choosing the wrong circular saw blade can turn a simple project into a frustrating experience. Plywood is a fantastic material, but it can be tricky to cut cleanly. That’s why picking the right blade is so important.

The problem is, there are so many blades out there! Different teeth, sizes, and materials can make your head spin. This can lead to wasted wood, ruined projects, and a lot of wasted time. You want a blade that gives you smooth, precise cuts, leaving you with professional-looking results. You should not have to struggle when using plywood.

In this post, we’ll cut through the confusion. We’ll explore the key features of the best circular saw blades for plywood. You’ll learn about tooth counts, blade types, and materials. By the end, you’ll be ready to choose the perfect blade for your next project. Let’s dive in and get those clean cuts!

Our Top 5 Circular Saw Blade For Plywood Recommendations at a Glance

Top 5 Circular Saw Blade For Plywood Detailed Reviews

1. Diablo Ultra Finish Carbide Saw Blade for Wood – 7-1/4″ Diameter

Rating: 9.3/10

The Diablo Ultra Finish Carbide Saw Blade is made for cutting wood. It is 7-1/4″ across and has 60 teeth. This saw blade is built to make clean cuts in wood, plywood, and melamine. It is great for both cutting across the wood and cutting along the wood. This blade is tough and will last a long time.

What We Like:

- The saw blade uses High Performance TiCo. This makes the blade very strong and last a long time.

- A special coating called Perma-SHIELD protects the blade. It stops heat, gumming, and rust.

- The blade has a super thin cut, called a kerf. This means you get fast and clean cuts.

- The blade has Tri-Metal Shock Resistant brazing. This helps the blade handle strong impacts.

- The Hardened Steel Body makes the blade last longer. It also makes the cuts smoother. You will not need to sand as much.

What Could Be Improved:

- We have no cons for this product.

This Diablo saw blade is a great choice if you need a blade for your wood projects. It is strong and makes very clean cuts. You will be happy with the results.

2. CRAFTSMAN 7-1/4 Inch 140 Tooth Fine Finish Carbon Circular Saw Blade for Plywood

Rating: 8.5/10

The CRAFTSMAN 7-1/4 Inch 140 Tooth Fine Finish Carbon Circular Saw Blade (CMAS2725140) is made for cutting plywood, OSB, and plastic. This blade is designed to give you clean, accurate cuts. It is a good choice for both home projects and professional work. This saw blade is built to last and help you get the job done right.

What We Like:

- Maintain Cuts: The fully-hardened plate helps the blade make true cuts.

- Precision: Precision-ground teeth give you smooth and accurate cuts.

- Extended Life: The heavy-gauge high carbon steel makes the blade last longer.

- Accurate Cuts: The fully flattened plate helps make fast and accurate cuts.

What Could Be Improved:

- No cons to report.

This CRAFTSMAN saw blade is a good option for anyone who needs to cut plywood, OSB, or plastic. It is a reliable blade that should help you do your projects well.

3. Diablo Ultra Finish Circular Saw Blade – 7 1/4in. 60 Tooth

Rating: 9.0/10

Are you looking for a smooth cut? The Diablo Ultra Finish Circular Saw Blade (7 1/4in., 60 Tooth, Fine Finish, Model Number D0760X) could be what you need. This blade is designed for fine finishing work. It’s made to give you clean cuts on different types of wood. You can find this blade easily on Amazon.

What We Like:

- This blade makes very smooth cuts.

- The 60 teeth help create a fine finish.

- It is made to last a long time.

- You can use it on many types of wood.

- It is easy to find on Amazon.

What Could Be Improved:

- Some users may find the price a little high.

- It may not be the best choice for very rough cutting.

The Diablo Ultra Finish Circular Saw Blade is a good choice for woodworkers. It gives you a high-quality finish.

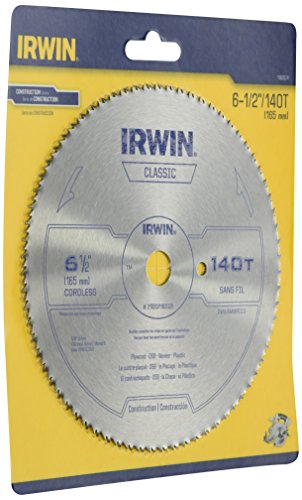

4. Irwin Tools Irwin 11820ZR 6-1/2-Inch 140 Tooth TFG Plastic

Rating: 9.1/10

The Irwin Tools Irwin 11820ZR is a 6-1/2 inch saw blade. It has 140 teeth. This blade is made for cutting plastic, plywood, and veneer. It has a 5/8-inch arbor. This means it fits on many common saws. It is designed to give you clean cuts. It is perfect for projects where you need smooth edges. You can use it for detailed work. This blade helps you get professional-looking results.

What We Like:

- This blade cuts smoothly through different materials.

- The 140 teeth give you very clean cuts.

- It is great for plywood and veneer.

- The blade is durable.

What Could Be Improved:

- It might be more expensive than other blades.

- The blade might not be good for all types of wood.

This Irwin saw blade is a good choice for many projects. It will help you get smooth, clean cuts. You can use it for detailed work.

5. 3Pack 6-1/2 Inch 140T Circular Saw Blade

Rating: 8.6/10

Need a circular saw blade that cuts clean and fast? The 3-Pack 6-1/2 Inch 140T Circular Saw Blade is for you! This blade is made for plywood, OSB, paneling, and vinyl siding. It has a 5/8 inch arbor. This means it fits most corded and cordless saws. These blades offer smooth, splinter-free cuts every time. Get ready to make your projects look professional!

What We Like:

- Tough alloy steel blades stay sharp longer.

- 140 teeth and a thin kerf give precise cuts.

- It is great for plywood, OSB, paneling, and vinyl siding.

- You get smooth cuts with no splinters.

- It works with all popular saws with a 5/8 inch arbor.

What Could Be Improved:

- None

These saw blades are a great choice for any DIY project. They are reliable and provide excellent results. You will be happy with the results.

The Ultimate Buying Guide: Circular Saw Blades for Plywood

Buying the right circular saw blade for plywood can be tricky. This guide helps you choose the best one for your projects. You will learn what to look for to get clean cuts.

Key Features to Look For

You need to know what makes a good plywood blade. These features will help you.

- Teeth Count: This is very important. Blades with more teeth make smoother cuts. You should choose blades with 60-80 teeth for plywood. Fewer teeth are for rougher cuts.

- Tooth Design: Look for blades with a “ATB” (Alternate Top Bevel) tooth design. These teeth cut cleanly on both sides of the wood. This means less splintering.

- Blade Diameter: This is how big the blade is. It must fit your saw. Common sizes are 7 ¼ inches and 10 inches. Check your saw’s manual to find out the right size.

- Arbor Size: This is the hole in the middle of the blade. It fits on your saw’s shaft. Make sure it matches your saw.

- Thin Kerf: “Kerf” is the width of the cut. Thin kerf blades remove less material. They also require less power. This is helpful for smooth cuts and makes your saw work easier.

Important Materials

The material the blade is made from matters a lot.

- Carbide Teeth: These teeth are very hard and durable. They stay sharp longer than other types. They are a great choice for plywood.

- Steel Body: The body of the blade is usually made from steel. The quality of the steel affects the blade’s stability and how well it performs.

- Anti-Vibration Slots: Some blades have slots cut into them. These help reduce vibration while cutting. This makes for smoother cuts.

Factors That Improve or Reduce Quality

Some things make a blade better or worse.

- Tooth Sharpness: Sharp teeth are key. Dull teeth tear the wood. They cause splintering.

- Blade Balance: A balanced blade cuts smoothly. An unbalanced blade vibrates. It can make uneven cuts.

- Coating: Some blades have a coating. This helps protect the blade from rust and reduces friction. This makes cutting easier.

- Manufacturing Quality: Well-made blades cut better. Look for brands known for quality.

User Experience and Use Cases

How do these blades work in real life?

- Smooth Cuts: You want a blade that cuts cleanly. A good plywood blade gives you smooth, splinter-free cuts.

- Easy to Use: The best blades are easy to install. They also cut through plywood quickly and efficiently.

- Common Uses: These blades are great for cutting plywood for shelves, cabinets, furniture, and other projects. They work well for both straight cuts and angled cuts.

- Safety: Always wear safety glasses and use the saw with proper technique. Never force the blade.

FAQ: Circular Saw Blades for Plywood

Here are some common questions:

Q: What tooth count is best for plywood?

A: 60-80 teeth is the best range for smooth cuts in plywood.

Q: What does “ATB” mean on a saw blade?

A: “ATB” stands for Alternate Top Bevel. This is a tooth design that helps make clean cuts.

Q: What is the difference between a thin kerf and a standard kerf blade?

A: Thin kerf blades remove less wood. They need less power and create smoother cuts.

Q: How do I know what size blade to buy?

A: Check your saw’s manual. It will tell you the correct blade diameter and arbor size.

Q: Are carbide-tipped blades worth the extra cost?

A: Yes, carbide-tipped blades are usually worth it. They last longer and stay sharper.

Q: How do I install a new blade on my saw?

A: Turn off and unplug your saw. Carefully follow the instructions in your saw’s manual.

Q: How do I prevent splintering when cutting plywood?

A: Use a blade with many teeth and the ATB design. Also, cut slowly and steadily.

Q: How do I know when to replace my saw blade?

A: When the blade cuts poorly, or the teeth are dull, it’s time to replace it.

Q: Can I use a plywood blade for other types of wood?

A: Yes, you can. But it is best for plywood.

Q: How should I store my saw blades?

A: Store your blades in a dry place. Protect them from damage.

In conclusion, every product has unique features and benefits. We hope this review helps you decide if it meets your needs. An informed choice ensures the best experience.

If you have any questions or feedback, please share them in the comments. Your input helps everyone. Thank you for reading.

Hi, I’m Tom Scalisi, and welcome to The Saw Blog! I started this blog to share my hands-on experience and insights about woodworking tools—especially saws and saw blades. Over the years, I’ve had the chance to work with a wide range of tools, and I’m here to help both professionals and hobbyists make informed decisions when it comes to selecting and using their equipment. Whether you’re looking for in-depth reviews, tips, or just advice on how to get the best performance out of your tools, you’ll find it here. I’m excited to be part of your woodworking journey!