Have you ever tried to cut plywood with a dull blade? It’s a frustrating experience! The wood tears, the saw chatters, and your project looks terrible. Choosing the right blade for your circular saw makes all the difference. Plywood is a great material for many projects, but it can be tricky to cut cleanly. Many people struggle with tear-out, splintering, and rough edges when they use the wrong blade. It’s a common problem that can ruin your work.

This blog post will help you understand the different types of blades you can choose from. We will explore the best options for cutting plywood and explain important details like tooth counts, blade materials, and kerf widths. By the end, you will know exactly how to pick the perfect blade for your specific projects. This will help you get smooth, clean cuts every time and improve your woodworking skills.

Now, let’s dive into the details of selecting the best blade for your plywood circular saw. We’ll cover everything you need to know to make your cuts perfect.

Our Top 5 Blade For Plywood Circular Saw Recommendations at a Glance

Top 5 Blade For Plywood Circular Saw Detailed Reviews

1. CRAFTSMAN 7-1/4 Inch 140 Tooth Fine Finish Carbon Circular Saw Blade for Plywood

Rating: 8.9/10

The CRAFTSMAN CMAS2725140 circular saw blade is made for cutting plywood, OSB, and plastic. It has 140 teeth for fine finishes. This blade helps you make smooth and accurate cuts. It is designed to last a long time and is a great tool for your projects.

What We Like:

- The blade’s fully-hardened plate helps keep cuts straight.

- Precision-ground teeth give smooth and accurate cuts.

- Heavy-gauge high carbon steel makes the blade last longer.

- The fully flattened plate allows for fast and accurate cuts.

What Could Be Improved:

- The blade’s initial cost might be higher than some other blades.

- The blade’s performance might be affected by the type of wood.

Overall, the CRAFTSMAN CMAS2725140 circular saw blade is a good choice for anyone who needs to cut plywood, OSB, or plastic. It’s a blade that can provide clean and precise cuts.

2. 3Pack 6-1/2 Inch 140T Circular Saw Blade

Rating: 9.4/10

Need a saw blade that cuts clean and fast? This 3-pack of 6-1/2 inch circular saw blades is made for you. These blades have 140 teeth and a 5/8 inch arbor. You can use them with plywood, OSB, paneling, and vinyl siding. They are designed to give you smooth cuts without splinters. These blades fit most corded and cordless saws.

What We Like:

- Tough alloy steel blades stay sharp longer.

- 140 teeth give you smooth and clean cuts.

- The thin kerf design helps with precision.

- Great for plywood, OSB, paneling, and vinyl siding.

- You will not get splinters.

- The blades work well for miter edges and cross cuts.

- They fit most popular saws.

What Could Be Improved:

- None at this time.

These saw blades are a smart buy if you do woodworking. They are a good choice for anyone who wants clean cuts.

3. Diablo Ultra Finish Carbide Saw Blade for Wood – 7-1/4″ Diameter

Rating: 8.6/10

The Diablo Ultra Finish Carbide Saw Blade is made for cutting wood. It’s a 7-1/4″ diameter blade with 60 teeth. This blade is designed for clean and fast cuts. It works great for crosscuts and rip cuts in wood, plywood, and melamine. This blade helps you get professional-looking results.

What We Like:

- The TiCo carbide is strong and lasts a long time.

- The Perma-SHIELD coating stops the blade from sticking and rusting.

- The thin kerf cuts wood quickly and smoothly.

- Tri-Metal brazing makes the blade tough and resistant to shocks.

- The hardened steel body keeps the blade sharp for a longer time. It also reduces the need for sanding.

What Could Be Improved:

- Some users may find the price a bit high.

- The blade is designed for wood. It is not for other materials.

In conclusion, the Diablo Ultra Finish Carbide Saw Blade is a top-notch choice for woodworkers. It offers a lot of great features that make cutting wood easy and precise.

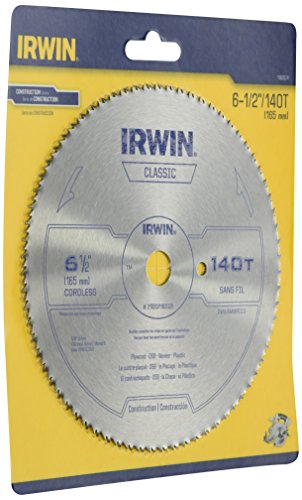

4. Irwin Tools Irwin 11820ZR 6-1/2-Inch 140 Tooth TFG Plastic

Rating: 9.4/10

The Irwin Tools 11820ZR saw blade is built to cut smooth. It is made for plastic, plywood, and veneer. This blade has 140 teeth, which means it can make very fine cuts. The blade is 6-1/2 inches across. It has a 5/8-inch arbor, so it will fit on many saws. It is designed to provide clean cuts, reducing the need for sanding or finishing work. This saw blade is a good choice for anyone who works with these materials.

What We Like:

- The blade gives very clean cuts.

- It works well on plastic, plywood, and veneer.

- The many teeth help make the cuts smooth.

What Could Be Improved:

- The specific price is not mentioned in the product, it is important to know the price.

- Durability over time is something we are unable to test.

This Irwin saw blade is a good tool for detailed work. It helps you make smooth cuts in plastic, plywood, and veneer. It is a great choice for your next project!

5. Diablo Ultra Finish Circular Saw Blade – 7 1/4in. 60 Tooth

Rating: 8.8/10

The Diablo Ultra Finish Circular Saw Blade – 7 1/4in. 60 Tooth, Fine Finish, Model Number D0760X is a blade for your circular saw. It is designed for fine cuts. This blade has 60 teeth. It will help you make smooth cuts in wood. You can buy this blade on Amazon. It’s a good blade for projects around your house.

What We Like:

- This blade makes clean cuts.

- It’s good for detailed work.

- The blade is durable. It lasts a long time.

- It is easy to install.

- The 60 teeth help make smooth cuts.

What Could Be Improved:

- The price is a bit higher than some other blades.

- It may not be the best for very rough cuts.

This Diablo saw blade is a great tool for woodworkers. It helps you create beautiful finishes. If you need a blade for fine cuts, this is a good choice.

Blade Buying Guide: Plywood Power!

Choosing the right blade for your circular saw can make cutting plywood easy. The wrong blade will make your cuts rough and splintered. This guide helps you pick the perfect blade!

Key Features to Look For

You need to know what to look for in a blade for plywood. Here’s what matters:

- Teeth Count: Blades have teeth. More teeth mean smoother cuts. For plywood, look for blades with a higher tooth count. Aim for blades with 60 to 80 teeth, or even more.

- Tooth Design: Different teeth designs cut differently.

- ATB (Alternate Top Bevel): These teeth are angled. They are great for smooth cuts in plywood.

- TCG (Triple Chip Grind): TCG blades are good for cutting through tough materials. They are not as good as ATB for plywood.

- Blade Diameter: Make sure the blade fits your saw! Check your saw’s manual. Common sizes are 7 ¼ inch and 10-inch.

- Arbor Size: This is the hole in the middle of the blade. It has to fit your saw. Again, check your saw’s manual.

Important Materials

What the blade is made of affects its performance.

- Steel: Blades are usually made of steel.

- Carbide Teeth: Carbide teeth are tough and last longer. These teeth are often used on good plywood blades. Carbide teeth stay sharp longer than steel.

Factors That Improve or Reduce Quality

Quality matters! Here’s what to consider:

- Tooth Grind: The way the teeth are ground affects the cut. Sharp teeth make clean cuts.

- Blade Thickness: A thinner blade cuts more easily. Thicker blades are more durable.

- Brand Reputation: Some brands are known for quality. Research brands before you buy.

- Price: You often get what you pay for. A more expensive blade might be better.

User Experience and Use Cases

Think about how you will use the blade.

- Smooth Cuts: A good plywood blade should leave a smooth edge. You want to avoid splinters.

- Easy to Use: The blade should cut smoothly. It shouldn’t vibrate too much.

- Use Cases: Plywood blades are great for many projects. You can use them for:

- Building shelves

- Making furniture

- Cutting flooring

- DIY projects

Frequently Asked Questions

Here are some common questions about plywood circular saw blades:

Q: What is the best tooth count for cutting plywood?

A: Blades with 60 to 80 teeth or more are generally best for smooth cuts.

Q: What is ATB tooth design?

A: ATB stands for Alternate Top Bevel. The teeth are angled, which helps make clean cuts in plywood.

Q: What is the difference between ATB and TCG?

A: ATB blades are best for smooth cuts in plywood. TCG blades are good for cutting tough materials, but not as good for plywood.

Q: How do I know what size blade to buy?

A: Check your circular saw’s manual. It will tell you what blade diameter and arbor size you need.

Q: What are carbide teeth?

A: Carbide teeth are very hard. They stay sharp longer than steel teeth.

Q: How can I prevent splinters when cutting plywood?

A: Use a blade with a high tooth count and sharp teeth. Also, cut with the good side of the plywood facing up.

Q: How do I maintain my plywood blade?

A: Keep the blade clean. Avoid cutting through nails or other hard objects. Store the blade properly when not in use.

Q: How do I know when to replace my blade?

A: When the blade becomes dull or if it starts to produce rough cuts or burn marks, it’s time for a replacement.

Q: Can I use the same blade for cutting other materials?

A: Some blades are designed for multiple materials, but plywood blades are specifically designed for plywood. Using the wrong blade can be dangerous.

Q: Where can I buy a plywood blade?

A: You can buy plywood blades at hardware stores, home improvement stores, and online retailers.

In conclusion, every product has unique features and benefits. We hope this review helps you decide if it meets your needs. An informed choice ensures the best experience.

If you have any questions or feedback, please share them in the comments. Your input helps everyone. Thank you for reading.

Hi, I’m Tom Scalisi, and welcome to The Saw Blog! I started this blog to share my hands-on experience and insights about woodworking tools—especially saws and saw blades. Over the years, I’ve had the chance to work with a wide range of tools, and I’m here to help both professionals and hobbyists make informed decisions when it comes to selecting and using their equipment. Whether you’re looking for in-depth reviews, tips, or just advice on how to get the best performance out of your tools, you’ll find it here. I’m excited to be part of your woodworking journey!