Imagine a bridge you cross every day. What keeps it strong against rain and rust? The answer often lies in a hidden hero: the corrosion inhibitor. These special chemicals work silently to protect metal structures, pipelines, and machines from breaking down. Without them, our world would quickly crumble under the relentless attack of rust.

Choosing the correct inhibitor is tricky business. Pick the wrong one, and you waste money and still face damage. Many products promise protection, but how do you know which formula truly fits your specific metal and environment? This confusion leads to costly repairs and shorter equipment life. It’s a real headache for engineers and property owners alike.

This guide cuts through the confusion. We will clearly explain what makes a good corrosion inhibitor work. You will learn to identify the best type for your needs, saving you time and ensuring long-lasting protection. Get ready to master the science of rust prevention!

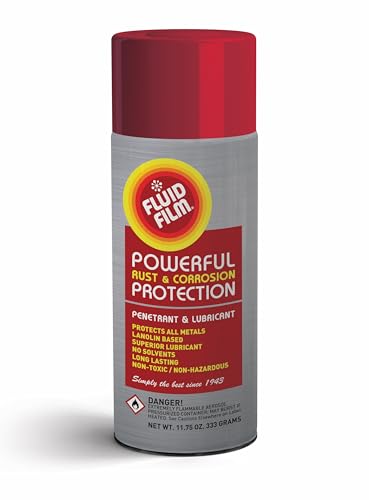

Top Corrosion Inhibitor Recommendations

- Coats metal parts to lubricate and protect against rust and corrosion by blocking out air and moisture. Protects for up to 2 years when used indoors and for up to 1 year when used outdoors

- Recommended for preventative maintenance or for protection in corrosive environments, such as hot and highly humid or cold, and winter atmospheres

- Included straw creates a precision stream of lubricant for controlled application and fastens to the notched cap for secure storage

- EFFECTIVE PROTECTION: Flexible corrosion inhibitor that protects and preserves metal surfaces; electrical connections; and engine components that are subjected to salt spray and high humidity.

- HEAVY DUTY: Provides extended corrosion protection indoors or outdoors.

- APPLICATIONS: Electrical connections (connections must be made first); engine components; equipment storage; fasteners; motors; salt spray protection; shaft; spindles; steering & throttle linkages.

- 2-in-1 Rust Solution: Converter + Inhibitor + Paint in One: Eliminate rust, prevent future corrosion, and refresh metal surfaces—all with a single application! This matte black formula acts as a powerful rust remover to dissolve existing rust, a long-lasting inhibitor to block new rust formation, and a durable paint coat to seal and protect. No need for multiple products or tedious prep steps—save time and money with this all-in-one metal care solution

- Versatile Application for All Metal Surfaces: Ideal for trailer/truck frames, cargo boxes, car chassis, boats, farm equipment, metal fences, tools, and more! Designed to adhere to ferrous metals (iron, steel) in both indoor and outdoor environments, it’s perfect for automotive repairs, marine maintenance, industrial projects, or household metal restoration. Whether you’re fixing a rusty trailer or protecting a boat hull, this paint delivers reliable results

- Ultra-Powerful Rust Fighting Formula: Engineered with advanced rust-converting technology, this 32oz formula penetrates deep into rusted layers to break down oxidation at the source. It transforms loose rust into a stable, paintable surface that bonds tightly with the metal—creating a barrier against moisture, salt, and other corrosive elements. Say goodbye to flaking rust and hello to a smooth, protected finish that lasts for years

- Boeshield Is Great For Use In Marine, Bicycles, Automotive, Tools, Rv'S, And Aviation

- Loosens Rusty And Corroded Parts And Is Safe On Paints, Any Metal Surfaces, Plastics, And Vinyl

- Flushes Out Dirt And Old Lubricants, Displaces Moisture, And Penetrates Moving Parts

- Coats metal parts to lubricate and protect against rust and corrosion by blocking out air and moisture. Protects for up to 2 years when used indoors and for up to 1 year when used outdoors.

- Recommended for preventative maintenance or for protection in corrosive environments, such as hot and highly humid or cold, and winter atmospheres

- Included straw creates a precision stream of lubricant for controlled application and fastens to the notched cap for secure storage

- Also provides effective protection for steering & throttle linkages

- Applications : Electrical connections, engine components, equipment storage, fasteners, motors, salt spray protection, shaft, spindles, steering & throttle linkages

- A long term, flexible corrosion inhibitor that protects & preserves metal surfaces, electrical connections, engine components & fasteners, subject to salt spray and high humidity

Choosing the Right Corrosion Inhibitor: A Buyer’s Guide

Corrosion is like rust eating away at metal. It weakens structures and costs a lot of money. A corrosion inhibitor is a chemical that slows this down. This guide helps you pick the best one for your needs.

1. Key Features to Look For

When you shop for a corrosion inhibitor, check these things first. These features tell you how well the product works.

- Inhibition Efficiency: This number shows how much rust the product stops. Higher percentages (like 95% or more) are usually better.

- Compatibility: Make sure the inhibitor works with your metal. Some work best on steel, while others are better for copper or aluminum.

- Ease of Application: Can you spray it on, brush it on, or do you need special equipment? Simple application saves time.

- Longevity: How long does the protection last? Some need reapplying every few months; others last for years.

Factors That Improve or Reduce Quality

The quality of an inhibitor depends on what’s inside and how you use it.

Ingredients Matter

Good inhibitors often use specific chemical compounds. For example, organic amines or molybdates create a protective layer on the metal surface. This layer acts like a shield. Cheaper, low-quality inhibitors might only offer a very thin, temporary barrier. Look for products listing clear, active ingredients.

Environmental Impact

Some older inhibitors contain harmful chemicals. Modern, high-quality inhibitors are often “green” or environmentally friendly. These are better for your health and the planet. Always check the safety data sheet (SDS).

Application Errors Reduce Quality

Even the best product fails if you use it wrong. If you apply it to a dirty, rusty surface, the protection won’t stick well. Proper surface preparation is crucial. Too thin an application also reduces its effectiveness.

2. Important Materials to Consider

Corrosion inhibitors are not one-size-fits-all. You must match the inhibitor to the material you want to protect.

Metal Type Protection

- Ferrous Metals (Iron/Steel): These are very prone to rust. Inhibitors designed for steel often work well in water systems or outside environments.

- Non-Ferrous Metals (Copper/Aluminum): These need different protection. Copper piping, for instance, requires specific inhibitors that do not react badly with copper.

- Mixed Systems: If you have pipes made of different metals touching, you need a universal inhibitor that protects all types simultaneously.

Form Factor

Inhibitors come in different forms. You might see them as liquids, powders, or vapor capsules (VCI). Liquids are common for coating surfaces or adding to water systems. Powders are sometimes used for packaging items.

3. User Experience and Use Cases

How the product feels to use and where you plan to use it greatly affect your choice.

Real-World Use Cases

- Industrial Machinery: Factories use inhibitors to protect equipment during downtime or shipment.

- Automotive: Coolant systems and undercarriages often need corrosion protection to fight road salt and water.

- Construction: Rebar (steel rods inside concrete) sometimes needs pre-treatment to stop rust from cracking the concrete later.

User Feedback

Read reviews! Users often report if a product is hard to mix, smells too strong, or if it truly lasts as long as advertised. A good user experience means easy handling and reliable, long-term protection. If many users complain about staining, avoid that product for visible areas.

Top 10 Frequently Asked Questions (FAQ) About Corrosion Inhibitors

Q: What exactly is corrosion?

A: Corrosion is when metal slowly breaks down, usually due to reaction with oxygen and water. Rust is the most common form of corrosion on iron.

Q: How do corrosion inhibitors work?

A: They create a thin, invisible barrier on the metal surface. This barrier stops water and oxygen from touching the metal, which stops the rusting process.

Q: Are all corrosion inhibitors safe for the environment?

A: No. Some older types use harsh chemicals. Always look for labels like “environmentally friendly” or check the safety data sheet (SDS) for warnings.

Q: Can I use a general-purpose inhibitor on all my metals?

A: It is best not to. Different metals need specific chemical formulas for the best protection. Check the product label carefully.

Q: How often should I reapply the inhibitor?

A: This depends on the product and the environment. Products for long-term storage might last years. Products exposed to harsh weather might need yearly checks or reapplication.

Q: What preparation is needed before applying the inhibitor?

A: You must clean the metal first. Remove all dirt, oil, and existing rust. A clean surface lets the inhibitor stick properly.

Q: Will an inhibitor change the color of my metal?

A: Most high-quality inhibitors dry clear or leave a very thin, almost invisible film. Some heavy-duty coatings might leave a slight oily residue or color tint.

Q: Are vapor corrosion inhibitors (VCI) better than liquid coatings?

A: VCIs release gas that protects hard-to-reach areas inside enclosed spaces, like inside an engine or a sealed box. Liquids are better for coating large, open surfaces.

Q: What is the difference between a rust preventative and an inhibitor?

A: A rust preventative is usually a thick coating applied before storage. An inhibitor is often a chemical added to a liquid (like water or oil) or sprayed on to slow down corrosion during active use.

Q: Can I mix two different brands of corrosion inhibitors?

A: Never mix them unless the manufacturer specifically says it is safe. Mixing chemicals can cause a reaction that makes the protection fail or even cause damage.

Hi, I’m Tom Scalisi, and welcome to The Saw Blog! I started this blog to share my hands-on experience and insights about woodworking tools—especially saws and saw blades. Over the years, I’ve had the chance to work with a wide range of tools, and I’m here to help both professionals and hobbyists make informed decisions when it comes to selecting and using their equipment. Whether you’re looking for in-depth reviews, tips, or just advice on how to get the best performance out of your tools, you’ll find it here. I’m excited to be part of your woodworking journey!

![WD-40 Specialist Corrosion Inhibitor, Long-Lasting Anti-Rust Spray, 6.5 OZ [6-Pack]](https://m.media-amazon.com/images/I/51cpAcaNyVL.jpg)