Have you ever watched your brand-new composite deck splinter and tear as you cut it? It’s frustrating, isn’t it? Composite decking is a fantastic choice. It’s durable and looks great. But cutting it can be tricky. The wrong saw blade can ruin your project.

Choosing the best circular saw blade for composite decking is a vital step in your project. There are so many blades available on the market today, but they aren’t all created equal—some are excellent for the job, while others are a poor fit. Picking the wrong one can lead to rough, jagged edges, wasted materials, and a lot of unnecessary headaches. You might even find yourself spending extra money to fix mistakes or losing valuable time on the job.

This blog post will help you. We’ll explore the best types of blades for your composite decking. You’ll learn what to look for and what to avoid. By the end, you’ll know exactly how to choose the perfect blade. Your cuts will be clean, and your deck will look amazing! Let’s dive in and make sure your next decking project is a success!

Our Top 5 Circular Saw Blade For Composite Decking Recommendations at a Glance

Top 5 Circular Saw Blade For Composite Decking Detailed Reviews

1. Diablo TrexBlade Saw Blade for Composites and Plastic – 7-1/4″ Diameter

Rating: 9.3/10

The Diablo TrexBlade Saw Blade is designed for cutting composite decking and plastic. It is a 7-1/4″ blade with 44 teeth. This blade is made to give you clean cuts. It helps you work on projects without problems. The blade uses special features to make cutting easier and last longer.

What We Like:

- TiCo Hi-Density Carbide helps the blade last a long time. It can handle wear and tear well. This makes it great for cutting tough materials.

- The Modified Triple Chip Grind (MTCG) keeps the material cool. This gives you clean cuts without melting.

- Perma-SHIELD coating keeps the blade clean. It stops the blade from sticking, getting hot, or rusting. This helps the blade work better and last longer.

- The Thin Kerf Design needs less power. This is good for saws that don’t have much power. It also helps make precise cuts without chipping.

- This blade gives great results in composite materials and cellular PVC. You will get a nice finish on your projects.

What Could Be Improved:

- The product description does not mention any cons.

The Diablo TrexBlade is a good choice for people who work with composite materials and plastics. This blade is made to make your work easier and give you great results.

2. Norske Tools NCSBP226 7-1/4 inch x 48T Composite Decking (Trex) and Bamboo Decking Saw Blade 5/8 inch Bore with Diamond Knockout Japanese Steel

Rating: 9.3/10

The Norske Tools NCSBP226 saw blade is made for cutting composite decking and bamboo decking. It’s a 7-1/4 inch blade with 48 teeth. This blade is designed to make clean cuts without melting the material. It’s made with Japanese steel and has a special coating to help it last longer.

What We Like:

- This blade cuts composite and bamboo decking well.

- The tooth design helps the blade cut cleanly.

- The non-stick coating helps the blade last.

- It has an ultra-thin design for fast cuts.

What Could Be Improved:

- Some users might prefer a different tooth count for specific materials.

In conclusion, the Norske Tools NCSBP226 saw blade is a good choice for cutting composite and bamboo decking. It’s a well-designed blade that helps you make clean cuts.

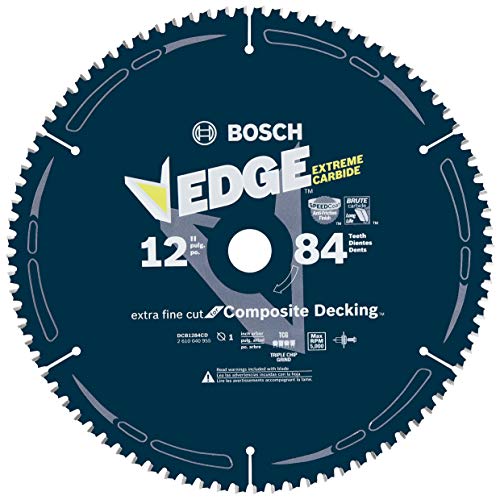

3. Bosch DCB1284CD 12 in. x 84-Tooth Composite Decking/Plastics Circular Saw Blade

Rating: 9.4/10

The Bosch DCB1284CD is a 12-inch circular saw blade. It has 84 teeth. It is made for cutting composite decking and plastics. This blade works well with miter saws and slide miter saws. It is designed to give you clean and precise cuts. The blade is built to last and perform well.

What We Like:

- This blade can cut many materials. You can cut composite decking, PVC, and other soft plastics.

- The blade’s tooth design helps it cut very well. It gives you a great finish.

- The blade is made of strong steel. It will not bend easily. This helps with accuracy.

- A special coating helps the blade last longer. It prevents heat and corrosion.

- It works with many 12″ miter saws.

What Could Be Improved:

- Specific performance details, such as the blade’s longevity in different materials, are not provided.

This Bosch blade is a good choice for anyone who cuts composite decking or plastics. It’s a durable and efficient blade that should make your cutting tasks easier.

4. DEWALT Circular Saw Blade

Rating: 9.2/10

The DEWALT Circular Saw Blade (DWA31740) is built for cutting composite decking. This blade is 7-1/4 inches across. It has 40 teeth to make clean cuts. The blade uses a special tooth design called a modified triple chip grind. The blade also has a laser-cut design. This helps the blade stay cool. It also makes cuts without metal.

What We Like:

- The blade is made for composite decking.

- The modified triple chip grind design cuts well.

- The laser-cut design helps the blade cut cleanly.

- The blade is 7-1/4 inches in diameter.

What Could Be Improved:

- It is only designed for composite decking.

This DEWALT saw blade is a good choice if you need to cut composite decking. The blade should make clean and precise cuts.

5. Bosch DCB1072CD 10 In. 72 Tooth Edge Circular Saw Blade for Composite Decking

Rating: 8.8/10

The Bosch DCB1072CD is a 10-inch circular saw blade. It has 72 teeth. This blade is made for cutting composite decking. It is designed for smooth and accurate cuts. The blade is built to last and handle tough materials. It works well with different types of saws.

What We Like:

- Tough Teeth: The blade uses Brute Carbide. This makes the teeth strong. They can resist damage and last a long time.

- Smooth Cuts: The blade uses a triple chip grind. This helps the blade cut smoothly and leaves a nice finish.

- Accurate Cuts: The blade has an extra-hard steel body. This keeps the blade straight. It resists bending. This makes for accurate cuts.

- Fast Cutting: The blade has a thinner kerf. This means it removes less material. This makes cuts faster. It also wastes less material.

- Works with Many Saws: This blade works with portable table saws and 10-inch miter saws. It is very versatile.

What Could Be Improved:

- Price: The blade is more expensive than other blades.

This Bosch blade is a good choice for cutting composite decking. It is designed for quality and durability. It will make your projects easier.

The Ultimate Buying Guide: Circular Saw Blades for Composite Decking

If you’re building a deck, you need a good saw blade. Composite decking is a popular choice. It’s made of wood fibers and plastic. This guide will help you pick the right circular saw blade for the job.

Key Features to Look For

You need a blade that works well with composite decking. Here are some important features:

- Tooth Count: More teeth mean smoother cuts. Blades for composite decking usually have more teeth. Look for blades with 40 to 80 teeth.

- Tooth Shape: Teeth come in different shapes. The best shape for composite decking is often a “Triple Chip Grind” (TCG) or a “Alternate Top Bevel” (ATB). These teeth cut well and last longer.

- Blade Diameter: Make sure the blade fits your saw. Common sizes are 7 ¼ inches and 10 inches. Check your saw’s manual.

- Kerf: The kerf is the width of the cut the blade makes. A thin kerf blade removes less material. This means less power is needed. It also means less waste.

- Anti-Vibration Slots: Some blades have slots. These slots help reduce vibration. Less vibration means a cleaner cut.

Important Materials

The materials used make a big difference in a blade’s performance.

- Blade Steel: The blade is usually made of steel. Look for high-quality steel. It will be stronger and last longer.

- Carbide Teeth: The teeth are usually made of carbide. Carbide is very hard. It can cut through composite decking without dulling quickly.

- Coating: Some blades have a coating. The coating helps prevent rust. It also reduces friction. This makes cutting easier.

Factors That Improve or Reduce Quality

Several things can affect how good a blade is.

- Brand Reputation: Some brands are known for making high-quality blades. Research different brands before you buy.

- Manufacturing Process: The way the blade is made matters. Blades made with precision are usually better.

- Price: You often get what you pay for. A more expensive blade may last longer and cut better.

- Storage: Store your blade properly. Keep it in a dry place. Protect it from damage.

User Experience and Use Cases

Think about how you will use the blade.

- DIY vs. Professional: A DIYer might need a blade for occasional use. A professional needs a blade that lasts all day.

- Cutting Tasks: Will you be making straight cuts? Or, will you be making angled cuts? Choose a blade that’s right for the job.

- Decking Material: Different composite decking materials can vary. Some are harder than others. Choose a blade that works well with your specific decking.

- Safety: Always wear safety glasses. Use the blade with the proper guards. Follow all safety instructions.

Frequently Asked Questions (FAQ)

Q: What is composite decking?

A: Composite decking is made from a mix of wood fibers and plastic. It is a common choice for decks.

Q: Why do I need a special blade for composite decking?

A: Composite decking is hard. A regular blade might dull quickly. A blade made for composite decking has teeth that are designed to cut this material.

Q: What does “tooth count” mean?

A: Tooth count is how many teeth a blade has. More teeth mean smoother cuts.

Q: What is “kerf”?

A: Kerf is the width of the cut the blade makes.

Q: What is a “Triple Chip Grind” (TCG) tooth?

A: A TCG tooth is a type of tooth shape. It helps the blade cut composite decking well.

Q: How do I know what size blade to buy?

A: Check your saw’s manual. The manual will tell you what size blade to use.

Q: How do I store my saw blade?

A: Store your blade in a dry place. Protect it from getting damaged.

Q: Can I use the same blade for wood and composite decking?

A: You *can*, but it’s not ideal. A blade made for composite decking is better for the job.

Q: How do I know when to replace my blade?

A: When the blade starts to make rough cuts or is difficult to use, it’s time for a new one.

Q: Should I use eye protection when cutting?

A: Yes! Always wear safety glasses when using a circular saw.

In conclusion, every product has unique features and benefits. We hope this review helps you decide if it meets your needs. An informed choice ensures the best experience.

If you have any questions or feedback, please share them in the comments. Your input helps everyone. Thank you for reading.

Hi, I’m Tom Scalisi, and welcome to The Saw Blog! I started this blog to share my hands-on experience and insights about woodworking tools—especially saws and saw blades. Over the years, I’ve had the chance to work with a wide range of tools, and I’m here to help both professionals and hobbyists make informed decisions when it comes to selecting and using their equipment. Whether you’re looking for in-depth reviews, tips, or just advice on how to get the best performance out of your tools, you’ll find it here. I’m excited to be part of your woodworking journey!