Wondering what the best way to measure a band saw blade is? Most of the time, you can just use a standard tape measure or a tool made specifically for checking blade length. But if you are in a tough spot—like if your blade snapped or you don’t have the original manual—you might need a different approach. This guide breaks down exactly how to measure your blade, so you can be sure you are getting the perfect fit for your machine.

Image Source: www.detroitbandsaw.com

Why Accurate Band Saw Blade Measurement Matters

Having the right band saw blade is essential for safe and efficient cutting. A blade that’s too long or too short won’t fit correctly on the saw, leading to problems like:

- Blade Slippage: A loose blade won’t stay on the wheels.

- Poor Cutting Performance: The blade may wander or vibrate excessively.

- Damage to the Saw: Incorrect tension can damage the frame, wheels, or bearings.

- Safety Hazards: A blade coming off during operation is dangerous.

Therefore, accurate band saw blade measurement is not just about convenience; it’s crucial for optimal performance and safety.

Key Band Saw Blade Dimensions

When determining how to determine band saw blade size, you need to know about these key dimensions:

- Length: This is the total length of the blade, measured as a continuous loop.

- Width: This is the distance from the tip of a tooth to the back edge of the blade.

- Thickness (Gauge): This refers to the blade’s thickness, impacting its flexibility and cutting aggressiveness.

- Tooth Pitch (TPI): The number of teeth per inch, dictating the smoothness and speed of the cut.

Methods for Band Saw Blade Measurement

Here are several methods for measuring band saw blade, depending on the situation:

1. Measuring a Broken Band Saw Blade

If your blade is broken, here’s how to accurately measure band saw blade length:

- Lay the Blade Flat: Place both pieces of the broken blade on a flat surface, aligning them carefully.

- Use a Tape Measure: Stretch a tape measure along the entire length of the blade, following its contours.

- Record the Measurement: The total length is your band saw blade length. Note this measurement precisely.

- Measure Blade Width: Use calipers or a ruler to measure the width of the blade.

- Measure Blade Thickness (Gauge): Use a caliper to measure blade thickness. This is your band saw blade gauge measurement.

- Count Teeth Per Inch (TPI): Use a ruler to measure one inch of the blade length, and then count the number of teeth in that area.

2. Measuring with a Band Saw Blade Length Gauge

A band saw blade length gauge simplifies the process of measuring band saw blade when you don’t have an existing blade.

- Set Up the Gauge: Most gauges consist of two adjustable points or wheels.

- Adjust the Gauge: Position the adjustable points or wheels so that the distance between them matches the desired blade length. Consult your saw’s manual for the specified length.

- Read the Measurement: The gauge will display the required band saw blade dimensions.

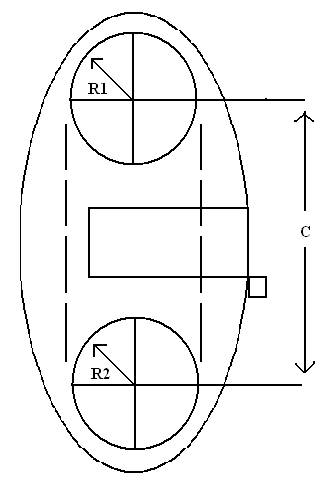

3. Measuring the Band Saw Directly (Circumference Method)

This method is useful when you don’t have a blade and can’t find the exact specifications. It involves measuring the circumference of the band saw wheels.

- Ensure Safety: Unplug the saw to prevent accidental start-up.

- Use a Flexible Measuring Tape: A cloth or flexible metal tape measure is best.

- Measure Wheel Circumference: Carefully measure the circumference of both the upper and lower wheels. Measure around the rubber tire on each wheel. This is best done with the tires in place, as they affect the overall measurement.

- Calculate the Blade Length:

- Add the two wheel circumferences together.

- Measure the distance between the centers of the wheels.

- Multiply this distance by 2.

- Add the result to the sum of the wheel circumferences. This total is an approximate band saw blade length.

The Formula: (Wheel 1 Circumference + Wheel 2 Circumference) + (2 * Distance between Wheel Centers) = Blade Length

4. Consulting Your Band Saw’s Manual

The best place to find the correct band saw blade size is your band saw’s manual.

- Locate the Manual: Find the manual that came with your band saw. If you’ve misplaced it, check the manufacturer’s website.

- Find Blade Specifications: Look for a section detailing blade specifications, including length, width, and thickness. The manual should provide precise band saw blade dimensions.

- Order the Correct Blade: Use the specifications in the manual to order the appropriate blade.

5. Using an Online Band Saw Blade Sizing Guide

Several online resources and manufacturer websites offer band saw blade sizing guide tools.

- Find a Reputable Guide: Search online for “band saw blade sizing guide” or visit the website of a band saw blade manufacturer.

- Enter Your Saw’s Information: Input the make and model of your band saw.

- Obtain Blade Specifications: The guide will provide the recommended blade length, width, and thickness.

Table Summarizing Measurement Methods

| Method | Pros | Cons |

|---|---|---|

| Measuring a Broken Blade | Simple and direct if the blade is available. | Requires careful alignment; potential for inaccuracies if the blade is stretched/damaged. |

| Band Saw Blade Length Gauge | Accurate and efficient for saws with known specifications. | Requires a gauge; not suitable for saws with unknown specifications. |

| Measuring the Saw Directly | Useful when no blade or specifications are available. | Less precise; requires careful measurement of wheel circumferences. |

| Consulting the Manual | The most reliable method; provides precise specifications. | Requires having the manual or access to it online. |

| Online Band Saw Blade Sizing Guide | Convenient and quick; provides readily available information. | Relies on accurate database information; may not cover all saw models. |

Factors Affecting Band Saw Blade Selection

Besides band saw blade measurement, consider these factors:

- Material to be Cut: Different materials require different blade types and tooth configurations. Wood, metal, and plastic each need specialized blades.

- Tooth Pitch (TPI): Higher TPI for smoother cuts in thinner materials; lower TPI for faster cuts in thicker materials.

- Blade Material: High-carbon steel blades are suitable for wood; bi-metal blades are more durable and ideal for metal cutting.

- Blade Width: Wider blades provide straighter cuts, while narrower blades are better for intricate curves.

Deciphering Band Saw Blade Width

Band saw blade width significantly impacts the type of cuts you can make.

- Wide Blades (3/8″ or wider): Best for straight cuts and resawing. They offer greater stability and resistance to bending.

- Narrow Blades (1/4″ or narrower): Ideal for cutting curves and intricate shapes. Their flexibility allows for tighter turns.

To determine the appropriate blade width, consider the smallest radius you need to cut. A narrower blade is necessary for tighter curves.

Fathoming Band Saw Blade Thickness (Gauge)

Band saw blade thickness (or gauge) affects the blade’s flexibility and cutting aggressiveness.

- Thicker Blades: More rigid, providing straighter cuts and handling higher tension. They are suitable for heavier-duty applications.

- Thinner Blades: More flexible, allowing for tighter curves and reducing material waste. However, they may be more prone to wandering.

Grasping Tooth Pitch (TPI)

Tooth pitch, or teeth per inch (TPI), is crucial for achieving the desired cut quality and speed.

- High TPI (14-24 TPI): Produces smoother cuts with less tear-out, ideal for thin materials and fine work.

- Low TPI (3-6 TPI): Cuts faster in thicker materials but may result in rougher edges.

- Variable Pitch Blades: Combine different TPIs to offer a balance of speed and smoothness, suitable for a range of material thicknesses.

A general rule is to have at least three teeth in contact with the material at all times.

Finding Correct Band Saw Blade: Step-by-Step Guide

Here’s a step-by-step band saw blade sizing guide:

- Identify Your Saw Model: Determine the make and model of your band saw.

- Consult the Manual: Check the owner’s manual for recommended blade specifications.

- Measure an Existing Blade: If available, measure the length, width, and thickness of your current blade.

- Determine the Material: Decide what materials you will be cutting most often.

- Choose the Appropriate TPI: Select a TPI suitable for the material thickness and desired cut quality.

- Consider Blade Material: Choose between high-carbon steel, bi-metal, or other specialized blade materials based on your needs.

- Order the Blade: Purchase the blade from a reputable supplier, ensuring it matches the required dimensions and specifications.

- Install and Tension the Blade: Follow the manufacturer’s instructions for proper blade installation and tensioning.

Common Mistakes to Avoid

- Rounding Measurements: Always use precise measurements. Rounding can lead to an incorrect fit.

- Ignoring Blade Width: Choosing the wrong blade width can limit your cutting capabilities.

- Over-Tensioning: Excessive tension can damage the blade and the saw.

- Neglecting Material Compatibility: Using the wrong blade material can result in poor performance and premature wear.

- Using Dull Blades: Dull blades increase the risk of kickback and produce poor-quality cuts.

Interpreting Blade Markings

Band saw blades often have markings that indicate their specifications. These markings may include:

- Manufacturer: The brand of the blade.

- Length: The blade’s total length.

- Width: The blade’s width.

- Thickness (Gauge): The blade’s thickness.

- TPI: The teeth per inch.

- Material: The type of steel used in the blade.

Familiarizing yourself with these markings will help you select the right blade for your needs.

Maintaining Your Band Saw Blade

Proper maintenance extends the life of your band saw blade and ensures optimal performance.

- Regular Cleaning: Remove sawdust and debris from the blade after each use.

- Proper Tensioning: Maintain the correct blade tension according to the manufacturer’s recommendations.

- Sharpness: Keep the blade sharp by honing or replacing it when it becomes dull.

- Storage: Store blades in a dry place to prevent rust.

Frequently Asked Questions (FAQ)

Q: How often should I replace my band saw blade?

A: Replace your band saw blade when it becomes dull, damaged, or starts to produce poor-quality cuts. The frequency depends on usage and the materials being cut.

Q: Can I use a longer or shorter blade than specified in the manual?

A: No. Using a blade that is significantly longer or shorter than specified can damage the saw and compromise safety. Minor variations might be possible with some saws, but always consult the manufacturer’s recommendations first.

Q: What is the difference between a skip tooth and a hook tooth blade?

A: Skip tooth blades have a gap between each tooth, making them suitable for cutting soft materials that produce a lot of sawdust. Hook tooth blades have a more aggressive tooth angle, ideal for cutting thicker materials quickly.

Q: How do I tension a band saw blade correctly?

A: Refer to your band saw’s manual for specific tensioning instructions. Most saws have a tension indicator or gauge. Adjust the tension until the indicator is within the recommended range.

Q: What does ‘bi-metal’ mean in reference to band saw blades?

A: A bi-metal blade is constructed with two different types of metal: a high-speed steel cutting edge welded to a flexible steel back. This combination provides durability and heat resistance, making it suitable for cutting metal and other tough materials.

By following this comprehensive guide, you can confidently measure band saw blade and choose the perfect blade for your needs, ensuring safe and efficient cutting for years to come.

Hi, I’m Tom Scalisi, and welcome to The Saw Blog! I started this blog to share my hands-on experience and insights about woodworking tools—especially saws and saw blades. Over the years, I’ve had the chance to work with a wide range of tools, and I’m here to help both professionals and hobbyists make informed decisions when it comes to selecting and using their equipment. Whether you’re looking for in-depth reviews, tips, or just advice on how to get the best performance out of your tools, you’ll find it here. I’m excited to be part of your woodworking journey!